© 2024 The authors. This article is published by IIETA and is licensed under the CC BY 4.0 license (http://creativecommons.org/licenses/by/4.0/).

OPEN ACCESS

A technology known as Total Dissolved Solid (TDS) sensor enables automatic monitoring and control of nutrients in Nutrient Film Technique (NFT) hydroponic systems. Nutrient automation system development, prototyping, and integration with relays, water pumps, and HC-SR04 ultrasonic sensors are some of the steps of this research. The objective of this research is to propose the fabrication and development of a prototype of an automated hydroponic system for pakcoy plants, which enables efficient nutrient delivery based on measured solution concentration levels. To monitor the water level and prevent water shortage, an HC-SR04 ultrasonic sensor is integrated into the system. Relays are used to switch on/off the pump and the water pump is used to control the water supply and nutrient solution automatically, with a notification delivery system via Telegram platform for remote monitoring. The results of this research include the development of a prototype nutrient delivery automation system that successfully integrates TDS sensors, relays, water pumps, and ultrasonic sensors. Performance evaluation of the prototype showed improved efficiency in nutrient and water management, as well as the system's ability to provide notifications regarding nutrient conditions to users. The integration of these sensors and communication platforms enables automated crop management, increasing the productivity of hydroponic farming. These findings confirm the potential of automation in improving the efficiency and sustainability of hydroponic farming systems.

hydroponics, nutrition, automation, Total Dissolved Solid sensor, pakcoy

Hydroponics is a growing trend in plant cultivation among farmers as it offers an easier, cleaner, and more efficient method compared to conventional methods that use soil. Hydroponics utilizes water enriched with nutrient solutions as a growing medium, replacing the role of soil as a nutrient provider and plant support [1, 2]. In hydroponic systems, nutrients are an important factor affecting plant growth, and optimal nutrient management is required to achieve maximum yields [3]. Generally, nutrients are monitored manually by farmers using a TDS meter to check nutrient concentrations on a daily basis [4]. However, this manual method often leads to errors in the regulation of water and nutrient levels due to fluctuations that occur due to absorption by plants and evaporation, as well as uncertainty in maintaining nutrient balance [5]. The need for automation in nutrient supply is important, as it can improve nutrient management efficiency and overall crop yields [6].

Pakcoy (Brassica rapa var. chinensis) is becoming one of the popular horticultural crops in hydroponic cultivation due to its high demand in the market and the health benefits it offers, such as abundant vitamin, mineral, and fiber content [7]. Pakcoy hydroponic cultivation offers the advantage of a relatively short harvest time, making it suitable for increasing productivity through hydroponic systems [8]. Based on the hydroponic encyclopedia, pakcoy requires nutrient concentrations in the range of 1050 ppm to 1400 ppm for optimal growth [9].

Various hydroponic methods have been used to supply nutrient solutions, including Nutrient Film Technique (NFT), Axis System, Deep Flow Technique (DFT), Flood & Drain, Drip, and Aeroponics [10]. In this study, the NFT method was chosen due to its ability to efficiently provide water, nutrients, and oxygen with a thin nutrient flow of ±3 mm in height at the plant roots [11]. However, despite the popularity of NFT systems, manual monitoring and management of nutrients is still a significant challenge.

Previous research has proposed the use of technology to monitor nutrient content in hydroponic systems. Some studies have used sensors to monitor the density of nutrient solutions, but not many have integrated a full automation solution capable of managing nutrient supply based on real-time conditions [12, 13]. The main gap encountered in this research is the lack of a system that can automatically control nutrient concentration and water level simultaneously in an NFT hydroponic system, with the remote monitoring feature of Telegram notifications of water level and nutrient values in the reservoir.

This research proposes a new solution in the form of an automatic nutrient delivery system that integrates a Total Dissolved Solids (TDS) sensor with a relay, a water pump, and an HC-SR04 ultrasonic sensor to monitor and regulate the nutrient concentration and water level in the reservoir automatically. The TDS sensor will measure the total solids content in the nutrient solution through electrical conductivity, while the ultrasonic sensor will monitor the water level to ensure a steady supply of nutrients [14]. In addition, the system is equipped with an LCD-based interface for live display of nutrient information, as well as integration with Telegram software that allows remote monitoring by farmers via mobile devices. Thus, the system overcomes the limitations of previous approaches by providing a fully automated solution that improves the efficiency of nutrient management and makes it easier for farmers to monitor the condition of pakcoy plants in NFT hydroponic systems on a regular basis. The solution proposed in this study not only provides convenience in nutrient monitoring and regulation, but also improves the precision of nutrient management, which can have a direct impact on increasing the productivity and sustainability of hydroponic pakcoy cultivation.

In order to create a strategy that is focused and pertinent to the goals and objectives, the research methodology in this study makes use of a framework. Figure 1 shows how the research technique is used. The phases are problem, approach, design, implementation, testing, and results.

Figure 1. Research methods

2.1 Problem

In this first phase, which addresses the issues faced by hydroponic farmers, the process of supplying nutrients and keeping an eye on hydroponic plants is still done manually or directly.

2.2 Approach

The requirements approach, which comprises hardware specifications utilized in the study, and the workings approach, which outlines the system's overall operation, comprise the approach stage.

2.3 Design

This research design goes through several stages: the design of the hardware used in the study is developed; the design is made as a block diagram to explain the interconnected diagram; the component schematic design describes the relationship as interconnected components; and the low level design is connected to the tool infrastructure as a network topology design.

2.4 Implementation

The process of putting everything that has been correctly designed into practice is known as the implementation stage. This step involves connecting every module to the circuit tool and configuring the microcontroller and additional hardware to execute the Arduino IDE application.

2.5 Measurement

At this point, a number of tests are conducted, specifically:

1. HC-SR04 ultrasonic sensor function testing.

2. Gravity TDS sensor function testing.

3. Relay function testing on DC motor, mini pump, water pump, and circulation pump.

4. Testing the LCD's functionality.

5. Testing the Ethernet Shield function.

6. Telegram functions testing.

2.6 Result

The study's ultimate product is an automated fertilizer delivery system for pakcoy grown in NFT hydroponics utilizing a TDS sensor. It operates effectively and is remotely monitored via Telegram.

In this study, the hydroponic nutrient delivery automation system was tested on a small scale using pakcoy plants as test objects. Tests were conducted to measure the accuracy of the TDS sensor, ultrasonic sensor, and the effectiveness of automatic nutrient and water delivery. The results obtained showed effective system performance, however, some limitations were found in terms of long-term.

1. TDS and nutrient sensor testing

TDS sensor accuracy: The test was conducted by comparing the TDS sensor readings with a manual measuring instrument (TDS meter). The average TDS sensor error value of 2.23% indicates that the sensor can read the nutrient concentration with fairly good accuracy, although there are small variations in the readings. The system managed to set up automatic nutrient feeding when the nutrient concentration dropped below 1050 ppm and stopped it when it reached 1400 ppm. In 10 tests, the system was able to keep the nutrient concentration within the optimal range for pakcoy growth, without manual intervention.

2. Ultrasonic sensor and water level testing

Ultrasonic Sensor Accuracy: Water level testing was done with an HC-SR04 ultrasonic sensor placed over the water reservoir. The test results showed that the sensor had 100% accuracy with 0% error rate, which means that the sensor successfully read the water level and triggered the water pump automatically when the water level dropped below 2 cm, and stopped when the level reached 13 cm. Water Filling Efficiency: The water pump worked efficiently, filling the reservoir in an average of 30 seconds per fill, with fill frequency adjusted according to evaporation rate and plant consumption.

3. Pakcoy plant growth testing

System testing was conducted over a 21-day pakcoy growing period, starting from planting the seedlings until they reached the full growth stage. Results showed that the nutrient automation system supported plant growth well. On day 14, the average height of pakcoy plants reached 12 cm, with fresh green leaves and no symptoms of nutrient deficiency. Plant growth was faster than the manual method based on previous observations where plants usually only reached 10 cm on day 14. This indicates that the automation system delivers nutrients more consistently and according to the needs of the plants.

4. System stability and long-term challenges

During testing, the system worked stably, but some issues arose regarding the durability of the sensors under hydroponic environmental conditions. The TDS sensor tends to experience a decrease in accuracy after 30 days of use due to residue buildup on the sensor, which requires further maintenance. In the simulated long-term use test, the system successfully maintained the automatic nutrient and water control functions, but the nutrient stirring using the DC motor needs to be optimized to prevent nutrient build-up in the larger reservoir.

The results were obtained after being reviewed in four stages below, starting with the first approach which was separated into two categories: requirements and work. Hardware design, schematic design, and network topology design comprise the second design stage. Third, the assembly or use of each component. Testing findings constitutes the fourth step.

3.1 Approach

3.1.1 Needs approach

The research on automatic nutrient delivery system for pakcoy plants using Total Dissolve Solids Sensor in telegram-based nutrient film technique hydroponics is at the stage of approaching the needs that will be implemented, can be assisted by hardware available to facilitate this research, as shown in Table 1.

Table 1. Needs approach (Hardware)

|

No. |

Hardware Requirements |

|

1 |

Arduino Uno R3 |

|

2 |

Gravity TDS V1.0 Sensor |

|

3 |

HC-SR04 Ultrasonic Sensor |

|

4 |

DC Motor 5V |

|

5 |

LCD I2C 16×2 |

|

6 |

Relay 5V |

|

7 |

Water Pump |

|

8 |

Mini Pump 5V |

|

9 |

Breadboard |

|

10 |

Jumper Cables |

|

11 |

Ethernet Shield |

|

12 |

Adapter |

(a) One of the most well-known microcontroller boards is the Arduino microcontroller. Arduino is an open-source electronic prototyping platform developed by Atmel that comes in the form of an electronic board (hardware) and a development environment (software). It makes use of the flexible and user-friendly Atmel AVR CPU type microcontrollers [15]. A Microcontroller boards based on the ATmega 238 are known by other names: Arduino UNO has 14 digital input / output pins (or commonly written I/O, where 14 of them can be used as PWM outputs including pins 0 to 13), 6 analog input pins, using 16 MHz crystals including pins A0 to A5, USB connection, power jack, ICSP header and reset button [16].

(b) The TDS sensor makes use of the electrical conductivity characteristics of water to measure the total solid content in a liquid. The strength of a solution's ability to conduct electricity is determined by its electrical conductivity. The TDS sensor measures in parts per million, or ppm. Hydroponics and home water analysis are two uses for TDS sensors in water quality applications [17]. A TDS meter is an instrument used in agriculture that is used to measure the concentration or density of nutrient solutions in hydroponic farming. This TDS sensor kit provides an analog output that is compatible with most microcontrollers, such as Arduino. requires a wide voltage input of 3.3~5.5V, and provides an analog voltage output of 0~2.3V, which makes it compatible with 5V or 3.3V control systems or boards such as Arduino, ESP32, Raspberry Pi, micro:bit and LattePanda. The excitation source is AC signal, which can effectively prevent the probe from polarization and extend the life of the probe, meanwhile it can help to improve the stability of the output signal. The TDS probe is waterproof, can be immersed in water for long time measurement [18].

(c) Ultrasonic sensor type HC-SR04 is one type of device used to measure the distance of a particular object. The advantage obtained from this sensor is a detection range of about 2-500 cm. This device uses two digital pins to communicate the distance read. The working principle of the HC-SR04 ultrasonic sensor is to transmit ultrasonic pulses of about 40 KHz, which can then be used to trigger an echo and shorten the specified time in microseconds. We can measure the pulse accurately 20 times per second, and this allows us to determine objects up to a distance of three meters [19].

(d) A DC motor is a robotic application-specific device that transforms DC electrical energy into spinning mechanical energy. In DC motors, the armature coil is referred to as the rotor (the rotating part) and the field coil as the stator (the non-rotating part). The yellow DC gearbox motor, which will be utilized as the motor for the stirrer in this study, has a speed of 100 rpm and a torque of 4 kg.cm. In its use, a gearbox with a certain gear ratio is required [20, 21].

(e) LCD (Liquid Crystal Display) is a type of display media that uses two materials that can polarize liquid crystals (Liquid Crystal) between the two sheets to display the required data characters from input devices such as sensors, display text, or display menus on microcontrollers. LCD screens are available in various versions, namely 8×2, 16×2, 20×2, 20×4, 40×4. In this tool, the size of the LCD type used is 16×2 LCD [22].

(f) Relay is an electronic device that can connect or disconnect a large electric current by utilizing a small electric current, besides that Relay is a Switch that works by using the principle of an electrically operated electromagnet and is an Electromechanical component consisting of 2 main parts namely coil and contact, coil is a coil of wire that gets an electric current, while contact is a kind of switch that is influenced by the presence or absence of electric current in the coil [23].

(g) Water pump is a submersible water pump motor that is used to raise water from lowlands to highlands or to drain water from low pressure areas to high pressure areas and also as a flow rate amplifier in a piping network system. The water pump uses a Brushless DC motor and works with a DC voltage of 12V 240L / H [24].

(h) Mini pump or commonly called Mini Submersible Water Pump is a small submersible water pump motor that can be operated without being immersed in water by sucking water using a water hose. Submersible pumps are a type of centrifugal pump. This mini subersible water pump has an electric voltage of 3-5.5V 120L / hour, the advantage of this mini water pump is that it is not noisy when used and is safe when working in water [25].

(i) One type of tool utilized for electronic prototype is the breadboard. When used, specifically as a jumper cable-connected medium conductor for electric current, it allows the current from one component to be linked correctly in accordance with the flow. Using a breadboard has several benefits, one of which is that since it is a board made without solder, constructed components are less likely to be damaged and are simpler to remove [26].

(j) Jumper cables are electrical wires used to connect components on a breadboard. There are connections or pins at the ends of jumper cables. There are three types of jumper cables: female to female, male to male, and male to male [27].

(k) A module called Ethernet Shield is used to link Arduino to the internet. For it to work, an Ethernet and SPI libraries are needed, and the Ethernet Shield uses an RJ-45 connection to connect to the internet, an integrated line transformer, and Power over Ethernet [28].

(l) An adapter is a circuit that is useful to convert high AC voltage to DC which is low. The adapter is an alternative replacement of DC voltage (such as batteries, batteries) because the use of AC voltage is longer and everyone can person can use it as long as there is electricity in that place [29].

3.1.2 Work approach

In this study, it will be explained how the system in this study works by identifying the operations shown in Figure 2. An explanation of the identification of this system can be seen in the accompanying graph.

Figure 2. Steps for working

Figure 2 describes the steps of this study and how the system operates, with the Arduino Uno serving as the primary control and data receiver.

(1) The Arduino receives the input data from the ultrasonic sensor and uses it to measure the water level. It then processes the data and sends the output to the water pump relay, which functions as an on/off switch for the water pump voltage.

(2) In addition, the Arduino provides output to the DC Motor Relay once again, acting as an on/off switch to move the DC Motor and stir the nutrient and water mixture in the container.

(3) Next, in order to measure the concentration of a nutrient solution, the TDS sensor will first read the solution's concentration value in PPM (Parts Per Million), a measuring unit used to determine the concentration of a material in a mixture or solution. Here, PPM is used to quantify the amount of nutrients present in the nutrient solution that is applied to the plants.

(4) The Arduino will transmit output to the mini pump relay, which functions as a small pump voltage on/off switch and a pump to spread the nutrient solution, if the concentration of the nutritional solution is less than the minimal limit, or ≤1050 PPM. If the concentration of nutrients is less than the minimum limit, the Arduino will send an output to the mini pump relay to open the mini pump voltage; if the concentration of nutrients is greater than the maximum limit, or ≥1400 PPM, the Arduino will close the relay voltage on the mini pump and DC motor relay, causing the mini pump to stop and distribute nutrients.

(5) Arduino will transmit text and numbers, representing the concentration value of a nutrient solution, to the LCD.

(6) The hydroponic tendon's water parameters and fertilizer solution concentration value will be processed by the Ethernet Shield linked to the Arduino and forwarded to Telegram through alerts.

(7) The Arduino will then provide output to the circulation pump relay after the process of providing water and nutrients is finished, and the relay will then supply power to the circulation pump to direct water into the hydroponic pipe.

3.2 Design

At this stage, several designs related to the research are carried out. The following are some of the stages of system design in this study.

3.2.1 Functional block diagram design

In this case, hardware design work is performed that is in line with the research being conducted. Based on the overall research, the following hardware design example is shown in Figure 3.

Figure 3. Functional block diagram

Ultrasonic HC-SR04 sensor as input reader of water level and volume, Gravity TDS V1 sensor as the input of a nutrient solution density reader, Arduino as a data receiver and sender, 5V Relay as an on and off switch on the Water pump, Mini pump, and DC Motor, water pump as an output to drain raw water, DC Motor as a stirrer of nutrient and water mixture, mini pump as an output to supply or distribute nutrient solutions, circulation pump as an output to distribute water and nutrient mixing, Ethernet Shield as an output that connects Arduino with the internet, while the LCD as an output that displays data in the form of characters or numbers. Displays text information on nutrient levels.

The control algorithm used in this system works by monitoring two main parameters: the concentration of nutrients in the water and the water level in the reservoir. This algorithm is executed through an Arduino UNO microcontroller that receives inputs from the installed sensors, then activates or deactivates the actuators (water pump and nutrient pump) through relays according to the conditions detected by the sensors.

1. Nutrient delivery control

- The TDS sensor is used to read the concentration of nutrients in the water, which is expressed in PPM (parts per million). If the sensor detects that the TDS value is lower than the minimum limit (1050 ppm), the Arduino will activate the relay to turn on the mini pump in charge of flowing the nutrient solution into the reservoir. Conversely, if the TDS value exceeds the maximum limit (1400 ppm), the relay will turn off the mini pump to stop the flow of nutrients.

- Whenever there is a change in nutrient concentration, the system also performs automatic stirring by activating a DC motor to ensure even nutrient distribution.

2. Water level control

An HC-SR04 ultrasonic sensor is used to measure the water level in the reservoir. When the water level drops below the set level (e.g., 2 cm from the bottom of the reservoir), a relay will activate the water pump to replenish the water. The pump will be turned off when the ultrasonic sensor detects that the water level has reached the upper limit (e.g., 13 cm from the bottom).

3.2.2 Schematic diagram design

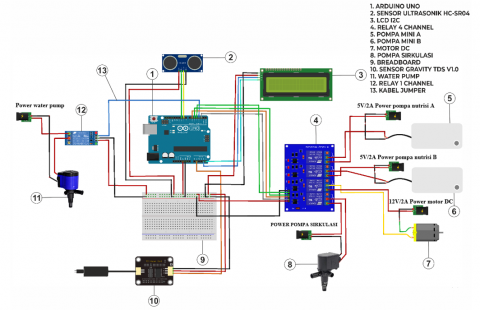

In the hardware-systematic circuit that the Arduino Uno will be attached to the relationship between the pins that have been identified as follows and the components that are linked using jumper wires is described in the hardware schematic design as shown in Figure 4.

Figure 4. Component schematic diagram

This hydroponic nutrition automation system is comprised of many essential components that function in unison, all of which are controlled by the Arduino UNO microcontroller-based architecture that forms the system's core.

TDS sensor measures the concentration of nutrients in water in ppm (parts per million). The sensor is directly connected to the microcontroller and transmits data in real-time. When the nutrient concentration falls below or rises above the specified limit (1050-1400 ppm), the microcontroller will activate or deactivate the nutrient pump automatically.

HC-SR04 ultrasonic sensor serves to measure the water level in the reservoir. The data from this sensor is used to automatically activate or turn off the water pump based on the detected water level.

Integration with telegram platform, the Arduino UNO microcontroller is equipped with an Ethernet Shield module that allows communication with the internet. The data obtained from the TDS sensor and ultrasonic sensor are sent to the Telegram platform via the internet network. Notifications about nutrient concentration and water level are sent to the user in real-time, enabling remote monitoring. Users can receive updates directly through the telegram bot, such as receiving critical condition notifications (e.g., water level is too low or nutrient concentration is inappropriate).

Relay and actuator system sensors are connected to relays that control the water pump, nutrient pump, and stirrer motor. The relays will be activated or deactivated based on the readings from the sensors, while the user can monitor the system remotely via telegram.

With this architecture, the system is able to provide automatic control over nutrients and water in hydroponics, while allowing efficient remote monitoring and control through integration with telegram.

3.2.3 Network topology design

The network topology design shows that the Ethernet Shield is connected to the switch and router, of course, the prototype series of pakcoy nutrition tools automatically using the TDS sensor in telegram-based NFT hydroponics has been programmed according to the programming instructions that have been made. The network architecture design can be seen in Figure 5.

Figure 5. Network topology design

From the internet source, it connects to the RB CCR 1009-7G-1C-1S+ proxy router with an IP address of 10.10.0.1/21. From the RB CCR 1009-7G-1C-1S+ router connects to the switch on the CSN (Computer System and Network) Laboratory Server, the switch connects to the hydroponic nutrient delivery device infrastructure having an IP address of 192.168.137.2/24. Then the hydroponic nutrient delivery infrastructure notifies the hydroponic ppm value to the telegram bot.

Applying security methods such as encryption, authentication, firewalls, and ACL settings has improved the security and dependability of communication between the Arduino and the server. Furthermore, in the research phase, buffering schemes, repetition mechanisms, QoS settings, and network redundancy implementations have been used to reduce network slowness and potential data loss. In order to identify problems early and guarantee that the hydroponic nutrient delivery automation system performs at its best, network performance monitoring is also utilized. It is expected that these enhancements will enable the network topology to maintain data security, improve communication dependability, and maximize the functionality of the Arduino-powered automated hydroponic nutrient delivery system for pakcoy plants.

This hydroponic nutrition automation system integrates the Telegram platform to facilitate monitoring and notifications to users. Through Telegram, users can receive periodic information regarding the nutrient and water conditions in the hydroponic system, which enables more effective management.

1. Notification function

Whenever the TDS sensor or ultrasonic sensor detects changes in nutrient concentration or water level, the system automatically sends notification messages to groups or private chats on Telegram. This notification includes information such as the current TDS value, the status of the water and nutrient pumps, and the water level in the reservoir. An example of the format of the message sent is: “Current nutrients: 1200 ppm, Nutrient Pump: ON, Water Level: 10 cm.”

In addition, if a critical condition occurs, such as a drop in water level below the minimum level or an excessively high nutrient concentration, the system will immediately send an alert to the user to take the necessary action.

2. Monitoring function

Users can access historical data through the telegram bot that has been developed, allowing them to review the changing trends of TDS value and water level over a specific period. This helps in data-driven decision making for better nutrient management.

Controlling Internet-connected nutrition delivery systems is particularly challenging when using third-party services like Telegram because to security concerns. A number of security measures have been put in place to deal with this issue:

- Data encryption and authentication: To protect private information, each communication session uses a telegram authentication token.

- Access control: To ensure that only authorized parties are in charge of the system, only authenticated users may access it or exercise control over it.

- Conduct monitoring: All system activities are logged to guard against illegal access and questionable conduct.

By implementing these security protocols, the system not only guarantees efficient operation via Telegram but also safeguards the integrity and security of hydroponic nutrition automation control against possible risks that can emerge from utilizing third-party platforms.

3.3 Implementation

The implementation stage necessitates the assembly or installation of all components, including TDS sensors, ultrasonic sensors, relays, pumps, and motors. These components are connected in accordance with the intended circuit scheme, and all devices are programmed using the Arduino IDE. To make sure every part function in accordance with the preset control algorithm, system testing is done. The system procedure will be used to carry out the following implementation tasks.

Figure 6. System workflow

The control algorithm in Figure 6 starts with the module connected to the Arduino UNO microcontroller, then initialize the system and start the program on the Arduino UNO microcontroller. Initialize all sensors and components such as TDS sensor to measure nutrient concentration, HC-SR04 ultrasonic sensor to measure water level, relay to control water pump, nutrient pump, DC motor, and circulation pump, LCD to display information, Ethernet Shield for communication with Telegram. For water level measurement, Read the ultrasonic sensor. Is the water level < 13 cm? Yes: Activate the water pump. No: Turn off the water pump. Next for nutrient concentration measurement, Read the TDS sensor. Is the TDS < 1050 ppm? Yes: Activate the nutrient pump and Activate the DC motor. No: Is TDS > 1400 ppm? Yes: Turn off the nutrient pump, and turn off the DC motor. No: Maintain pump and motor condition. For circulation pump control, Is the water level and TDS within the optimal range? Yes: Activate the circulation pump. No: Turn off the circulation pump. In the monitoring and notification stage, Display data on LCD, Send data to telegram. Is there a critical condition? Yes: Send alert notification to telegram. No: Continue monitoring. Wait for the time interval. Return to water level measurement.

3.4 Measurement

Currently, Arduino UNO, HC-SR04 ultrasonic sensor, TDS sensor, relay for water pump, dc motor, mini pump and circulation pump, I2C LCD, Ethernet Shield, and Telegram are used to test the features of the automatic nutrition system for pakchoy plants in NFT hydroponics. This testing is carried out to ensure that the tool being built is in accordance with the anticipated purpose.

3.4.1 HC-SR04 ultrasonic sensor function testing

Tests were carried out with the HC-SR04 ultrasonic sensor placed on top of the reservoir by emitting ultrasonic waves to the surface of the water then measured and compared with measurements using a ruler as shown in Figure 7.

Figure 7. HC-SR04 ultrasonic sensor function testing

When the ultrasonic sensor detects the water level is more than 13 cm or the water in the hydroponic reservoir is empty, the relay will be on to turn on the water pump and water will flow into the hydroponic reservoir, otherwise when the ultrasonic sensor detects the water level is less than 2 cm or the water in the hydroponic reservoir is full, the relay will be off.

Table 2. HC-SR04 ultrasonic sensor testing results

|

No. |

Water Distance Tandon (cm) |

Water Distance to Ultrasonic Sensor (cm) |

Reading Status |

Difference |

Error (%) |

|

1 |

14 cm |

14 cm |

Read, Water pump delivers water |

0 |

0 |

|

2 |

13 cm |

13 cm |

Read, Water pump delivers water |

0 |

0 |

|

3 |

12 cm |

12 cm |

Read, Water pump delivers water |

0 |

0 |

|

4 |

11 cm |

11 cm |

Read, Water pump delivers water |

0 |

0 |

|

5 |

10 cm |

10 cm |

Read, Water pump delivers water |

0 |

0 |

|

6 |

9 cm |

9 cm |

Read, Water pump delivers water |

0 |

0 |

|

7 |

5 cm |

5 cm |

Read, Water pump delivers water |

0 |

0 |

|

8 |

4 cm |

4 cm |

Read, Water pump delivers water |

0 |

0 |

|

9 |

3 cm |

3 cm |

Read, Water pump delivers water |

0 |

0 |

|

10 |

2 cm |

2 cm |

Read, Water pump stops delivering water |

0 |

0 |

Based on the results of testing the measurement of water distance on the HCSR04 ultrasonic sensor with a ruler / ruler as a measuring tool for comparison carried out 10 times and can be seen in Table 2, the data obtained is the result of an error of 0% so that it shows the test results are accurate. Measurements are made by placing the sensor with a measuring instrument (ruler) equal to its height in the hydroponic reservoir.

3.4.2 TDS sensor function testing

This stage is carried out to test the function of the TDS sensor in the system.

The purpose of the TDS sensor test is to measure the total nutrient solution dissolved in water. The process of testing nutrients in hydroponic reservoirs is carried out by comparing the value of the TDS sensor with the TDS-3 brand TDS meter measuring instrument dipped in water in the reservoir. In collecting sensor test data, the sensor is placed in a hydroponic reservoir which can be seen in Figure 8.

Figure 8. TDS sensor function testing

The TDS sensor value increases in Table 3, as the amount of dissolved solids in the water used to read the nutrient concentration value increases. Dissolved solids in water are contaminants between raw water and AB mix nutrient solution. The PPM values contained in Table 3 are calculated using the following formula:

x=(133,42∗v3−255,86∗v2+857,39∗v)∗0,5 (1)

TDS value is represented by the x symbol in the PPM calculation formula, while compensating voltage is represented by the v symbol.

The results of measuring the value of the TDS sensor and the TDS meter brand TDS-3 obtained various difference values between the TDS sensor and the TDS meter in each data collection, because the TDS sensor in the measurement can change in a fraction of a second and the stirring of nutrients is evenly distributed so that the difference between the TDS meter and the TDS sensor is not too far away. The average error value or error value of the nutrient reading on the tool is 2.23%, where this calculation uses the formula for the average error value [30]. From the results of the nutrition experiment, it can be concluded that the tool has successfully controlled the amount of nutrients in the hydroponic pakcoy plant.

Table 3. TDS sensor testing results

|

Testing |

TDS Sensor (ppm) |

TDS Meter (ppm) |

Difference |

Error (%) |

|

1 |

190 |

170 |

20 |

11.7% |

|

2 |

718 |

732 |

14 |

1.91% |

|

3 |

853 |

850 |

3 |

0.35% |

|

4 |

938 |

900 |

38 |

4.22% |

|

5 |

1077 |

1087 |

10 |

0.91% |

|

6 |

1099 |

1101 |

2 |

0.18% |

|

7 |

1103 |

1110 |

7 |

0.63% |

|

8 |

1121 |

1124 |

3 |

0.27% |

|

9 |

1264 |

1271 |

7 |

0.55% |

|

10 |

1250 |

1270 |

20 |

1.62% |

|

Average |

12.5 |

2.23% |

||

3.4.3 Relay function testing

1. Testing the relay function on the water pump

The relay function testing stage on the water pump is tested when the ultrasonic sensor detects water in an empty hydroponic reservoir, then the relay switches On and turns on the water pump to drain water into the reservoir, otherwise when the ultrasonic sensor detects water in a full hydroponic reservoir, the water pump relay switches Off. The tests the function of the water pump relay in Figure 9.

Figure 9. Testing the relay function on the water pump

2. Relay function testing on DC motor

Testing the relay function on the DC Motor is tested by turning on the DC Motor which is connected to a 4 channel 5VDC relay at IN3 which functions as a stirrer between mixing water and nutrient solutions to be evenly distributed and the TDS sensor reading is maximized. The condition where the DC motor turns on or the relay switches on if the water pump has finished draining the water in the hydroponic reservoir, then the DC motor will turn on and stir the water while the mini pump provides nutrient solution to the hydroponic reservoir. The tests the DC Motor relay function in Figure 10.

Figure 10. Relay function testing on DC motor

In Figure 10 is a condition where the relay and DC Motor are off and on. The relay lamp on IN3 that connects the DC motor with the relay will turn off if the relay switches off as well as the DC motor will be off and the IN3 relay lamp will light up if the relay switches on, the DC motor is also on.

3. Relay function testing on mini pump

Testing the relay function on the mini pump is tested by turning on 1 mini pump connected to a 4 channel 5VDC IN1 relay as an output to channel the AB Mix nutrient solution to the hydroponic reservoir from the TDS sensor reading. Before testing the relay function on this mini pump, it is necessary to first make the AB Mix nutrient solution before it is distributed to the hydroponic reservoir, namely nutrient solution A and nutrient solution B which can be seen in Figure 11.

Figure 11. AB mix nutrition

Figure 11 shows the making of AB Mix nutrients needed for relay testing on this mini pump by mixing nutrient solution A and nutrient B, each using a 250 ml bottle which is combined into the AB Mix nutrient solution container.

Relay testing on the mini pump is done when the TDS sensor reads the ppm value below the minimum limit, then the relay switches On and turns on the AB Mix nutrient mini pump to distribute nutrients, otherwise when the TDS sensor reads the ppm value has met the nutritional needs at a predetermined set point, the AB Mix nutrient mini pump relay switches Off and turns off the mini pump. Before that is done for the manufacture of AB Mix nutrients that are mixed. The test of the mini pump relay function is shown in Figure 12.

Figure 12. Relay function testing on mini pump

In Figure 12, the IN1 relay light that connects the AB Mix mini nutrient pump lights up, which means the relay switches on and the mini pump is also on or distributing nutrients to the hydroponic reservoir.

4. Relay function testing on the circulation pump

The last stage of testing the relay function, namely the circulation pump relay, is tested by turning on the circulation pump connected to the 4 channel 5VDC IN4 relay as an output to drain the mixing between water and nutrient solution in the hydroponic reservoir to the PVC pipe contained in the NFT hydroponic circuit. The condition of the relay switch On on the circulation pump is when the provision of nutrients has been carried out automatically and read by the TDS sensor has met the nutritional needs that have been needed, the circulation pump will turn on and flow into the PVC pipe in a circulated manner. The test of the circulation pump relay function is presented in Figure 13.

In Figure 13, the IN4 Relay light that connects the Circulation Pump lights up which means the relay switches on and the circulation water pump turns on to drain nutrients into the NFT hydroponic pipes.

Figure 13. Relay function testing on the circulation pump

Table 4. Relay function testing results

|

No. |

Relay Initial Condition |

Relay Testing |

Delay When Turning On and Off |

Result |

|

1 |

Normally Open (NO) |

Water Pump |

1 second |

Retrieved |

|

2 |

Normally Open (NO) |

DC Motor |

1 second |

Retrieved |

|

3 |

Normally Open (NO) |

Mini pump A and Mini pump B |

1 second |

Retrieved |

|

4 |

Normally Open (NO) |

Circulation Pump |

1 second |

Retrieved |

Table 4 shows the relay function works according to the program that has been made. In the field of electricity, NO stands for Normally Open, which means that under everyday situations it is miles open, in other words here it explains that the Water Pump, DC Motor, Mini Pump A and B, and Circulation Pump which have the initial role of open circuit and have a delay of 1 second to flow electricity. The touch will remain in the open circuit position. To signify the contact to the closed circuit, we wish to press the actuator. The cutting edge will begin to flow when the contact is in a closed circuit. The cutting edge will begin to flow when the contacts are in a closed circuit. Open and closed conditions on contacts or relays serve as representations of logic gates.

3.4.4 LCD I2C function testing

The purpose of LCD (Liquid Crystal Display) testing is whether the LCD screen can display program information that will later appear on the LCD screen.

Figure 14. LCD I2C function testing

Figure 14 presents tests of the function of the I2C LCD. in this condition the LCD is programmed with the Arduino UNO. The LCD displays the text “AUTO HYDROPONICS ACTIVATED”. If the system is running, the text "TDS Value =... PPM, NUTRITION AB = ON/OFF" will appear.

3.4.5 Ethernet Shield function testing

In this Ethernet Shield test, it is carried out to find out whether the Ethernet Shield is connected or not to the internet network so that it can send data on nutritional values and water parameters to telegram on the hydroponic automation system. To see it, the test was carried out on the Arduino IDE serial monitor which can be seen in Figure 15.

Figure 15. Serial display monitor Ethernet Shield function testing

Figure 16. Ethernet Shield module

Figure 16 shows that all the Ethernet Shield lights are on, which means the Ethernet Shield is connected to the internet and can send data to telegram.

3.4.6 Telegram function testing

This test is carried out as a notification, where this system will send a telegram message in the form of a text regarding the condition of the hydroponic tank by displaying the distance of the water and the nutritional value (ppm) obtained from the ultrasonic sensor and TDS readings which will be stored in the hydroponic automation system database and find out the nutritional value information and whether the water level meets requirements or not.

Figure 17 shows the steps taken to test the functions on Telegram. This test is carried out as a notification. This system will send telegram messages in the form of text.

Figure 17. Telegram function testing

Figure 18. Serial display monitor telegram function testing

Figure 18 shows the serial monitor display when the infrastructure detects the water distance in the reservoir and the ppm value of the hydroponic nutrients, thereby providing a message to Telegram.

3.4.7 Overall testing and analysis of pakcoy crop system

This NFT hydroponic automation system was tested on pakcoy plants. The results of the experiment in the form of growth stages of the pakcoy plant can be seen in the following Figures 19-26.

Figure 19. Pakcoy seeds from the seedings process

Figure 20. Pakcoy growth day-3

Figure 21. Pakcoy growth day-7

Figure 22. Pakcoy growth day-14

Figure 23. Pakchoy growth day-21

Figure 24. Consistency of sensor data

Figure 25. Accuracy of automatic nutrient dosing

Figure 26. Impact on plant growth

Growing pakcoy was tested for 21 days in order to assess the overall efficacy of the hydroponic nutrient automation system. The manual technique served as a control during the test period to examine the effects on plant development, the stability of the sensors, and the accuracy of the automatic fertilizer delivery system.

1. Consistency of sensor data

- To guarantee reading consistency over an extended period of time, the TDS sensor and ultrasonic sensor were often checked. The average inaccuracy of the TDS sensor's measurements was found to be 2.23%, based on observations. During the 21-day test period, there was no discernible decline in sensor performance; nevertheless, there were some minor oscillations that could have been caused by changes in the reservoir's nutrient levels.

- When the water level was measured manually, the ultrasonic sensor performed steadily and had 0% reading error. The water pump was automatically turned on and off by the sensor's accurate detection of changes in water level.

2. Accuracy of automatic nutrient dosing

- The automated system accurately regulates nutrient delivery based on the TDS sensor reading. At nutrient concentrations below 1050 ppm, the nutrient pump is activated to add AB mix solution, and stops when the concentration reaches 1400 ppm.

- For 21 days, the automatic nutrient feeding kept the concentration within the desired range. No cases of overfeeding or underfeeding were detected. This consistency of nutrient delivery ensured that the plants received the optimal dose of nutrients at all times.

3. Impact on plant growth

- Pakcoy plant growth was monitored and measured every seven days during the test period. The average plant height at day 21 was 17 cm for the automated system, indicating that the automation system delivered nutrients more consistently.

- In addition, the leaves of the pakcoy plants using the automated system looked greener and fresher, indicating that nutrients were being delivered precisely according to the needs of the plants.

Table 5 presents the quantitative data obtained during the test.

Table 5. Quantitative data

|

Day |

Plant Height (Automatic) |

Plant Height (Manual) |

Automatic TDS Concentration (ppm) |

Manual TDS Concentration (ppm) |

|

3 |

3 cm |

3 cm |

1099 |

1101 |

|

7 |

7 cm |

6 cm |

1103 |

1110 |

|

14 |

12 cm |

10 cm |

1121 |

1124 |

|

21 |

17 cm |

16 cm |

1250 |

1270 |

To assess the system's performance under varied operating settings, testing of the hydroponic nutrient automation system was carried out in many situations. In order to determine how the system reacts to variations in water and nutrients, tests were carried out in two primary scenarios: normal and severe.

- Normal scenario:

The system maintains the nutrient concentration in the range of 1050-1400 ppm with an average of 1200 ppm, and successfully regulates the water level automatically.

- Extreme condition scenario:

In a simulated rapid nutrient drop, the system responds within 10 seconds and recovers the concentration within 5 minutes. The water pump fills the reservoir to the optimal limit in 30 seconds when the water is low.

During the testing phase, several limitations were encountered that could affect the performance of the system in the long run.

- TDS sensor accuracy limitations:

While the system works well in maintaining nutrient concentration, the TDS sensor tends to suffer from decreased accuracy over time due to particle buildup in the nutrient solution. To address this issue, regular cleaning of the sensor is required to maintain optimal performance.

- Pump performance under extreme conditions:

Under conditions of frequent water replenishment, such as when there is high evaporation or when a lot of water is absorbed by the plants, the water pump experiences a high workload. This causes the pump to work harder and risks premature wear. The proposed solution is to use a more durable water pump or add a backup pump that can work alternately.

- Uneven stirring of nutrients:

In larger scale usage scenarios, the stirring motor in this system is less effective in distributing nutrients evenly across the reservoir. This leads to small variations in nutrient concentration in some parts of the system. Using a stirring motor with more power or adding multiple stirring motors to a larger reservoir can be a solution to this problem.

In conclusion, the integration of TDS sensor technology with NFT hydroponic systems has presented an effective paradigm for automating nutrient delivery in pakcoy plants. The careful system design incorporating the TDS sensor, ultrasonic sensor, relay, water pump, and DC motor on an Arduino UNO results in a cohesive and efficient mechanism. Notably, the system excels at regulating nutrient supply via the TDS sensor, monitoring water level using the ultrasonic sensor, and controlling nutrient and water supply via the relay-controlled pump. The system is also integrated with Telegram, allowing regular remote monitoring of nutrient and water parameters, fulfilling the objectives set out in the introduction. Although it has certain limitations, such as the need to improve the accuracy of solution stirring and the dependence of TDS and ultrasonic sensors, these limitations offer insightful information for further research and development. Development challenges for larger scales, including multi-tank management, require more sophisticated controls and integration of additional sensors such as pH and water temperature sensors. Going forward, further research should prioritize refining the precision of the sensors and improving the overall robustness of the system, especially in wider scalability for different crop types and integration with more advanced IoT technologies. This continuous development is critical to ensure the success and viability of hydroponic nutrient automation systems in the real world. Stakeholders considering the adoption of this technology should appreciate its proven functionality while paying attention to areas that can be improved, encouraging collaboration between developers and industry practitioners to realize the full potential of this innovative solution in hydroponic farming practices.

[1] Muhasin, H.J., Gheni, A.Y., Tajuddin, N.I.I., Izni, N.A., Jusoh, Y.Y., Aziz, K.A. (2024). A systematic literature review for smart hydroponic system. Bulletin of Electrical Engineering and Informatics, 13(1): 656-664. https://doi.org/10.11591/eei.v13i1.4738

[2] Sharma, N., Acharya, S., Kumar, K., Singh, N., Chaurasia, O.P. (2018). Hydroponics as an advanced technique for vegetable production: An overview. Journal of Soil and Water Conservation, 17(4): 364-371. https://doi.org/10.5958/2455-7145.2018.00056.5

[3] Krisna, I.M.A., Wijana, G., Darmawati, I.A.P. (2023). Effect of AB mix concentration and frequency of liquid organic fertilizer spray (POC) on the growth of pakcoy (Brassica rapa L.) plants in the deep floating technique (DFT). Journal on Agriculture Science, 13(1): 40-53. https://doi.org/10.24843/AJoAS.2023.v13.i01.p04

[4] Kurniawan, A., Lestari, H.A. (2020). Sistem kontrol nutrisi floating hydroponic system kangkung (ipomea reptans) menggunakan Internet of Things berbasis telegram. Jurnal Teknik Pertanian Lampung, 9(4): 326. https://doi.org/10.23960/jtep-l.v9.i4.326-335

[5] Sulaiman, S.F., Kassim, A.H.A., Samsudin, S.I., Sulaiman, N.A., Sunar, N. (2023). IoT-based monitoring system for hydroponics. Przeglad Elektrotechniczny, 8. https://doi.org/10.15199/48.2023.08.24

[6] Chowdhury, M.E.H., Khandakar, A.; Ahmed, S., Al-Khuzaei, F., Hamdalla, J., Haque, F., Reaz, M.B.I., Al Shafei, A., Al-Emadi, N. (2020). Design, construction and testing of IoT based automated indoor vertical hydroponics farming test-bed in Qatar. Sensors, 20(19): 5637. https://doi.org/10.3390/s20195637

[7] Zudri, F., Nofrianil, N. (2023). Produksi tanaman pakcoy (Brassica rapa L.) pada berbagai jenis media tanam secara hidroponik. Agrohita Jurnal Agroteknologi Fakultas Pertanian, 8(1): 242-247. https://doi.org/10.31604/jap.v8i1.10471

[8] Rahman, N.A., Umar, M.Z., Putri, R.M.E., Fevria, R. (2022). Budidaya hidroponik tanaman pakcoy (Brassica rapa L.) menggunakan sistem nutrient films technique (NFT). Prosiding Seminar Nasional Biologi, 2(2): 743-750. https://doi.org/10.24036/prosemnasbio/vol2/503

[9] Bayu, W.N. (2023). Tabel PPM dan pH Nutrisi Hidroponik. https://hidroponikpedia.com/tabel-ppm-dan-ph-nutrisi-hidroponik.

[10] Rozilan, M.R., Mohd Rodzi, A.S., Faiz Zubair, A., Hemdi, A.R., Deraman, R., Md Sin, N.D. (2023). Design and fabrication of nutrient film technique (NFT) hydroponic system. In Advancement in Instrumentation & Human Engineering. ICMER 2021. Lecture Notes in Electrical Engineering, vol. 882. Springer, Singapore. https://doi.org/10.1007/978-981-19-1577-2_11

[11] Ali, M.S.A.B.M., Nordin, M.K.B., Zaki, M.H.B.M., Saaid, M.F.B. (2024). Optimizing plant growth in indoor NFT hydroponic systems: Design, environmental monitoring, and analysis. In 2024 IEEE International Conference on Applied Electronics and Engineering (ICAEE), Shah Alam, Malaysia, pp. 1-6. https://doi.org/10.1109/ICAEE62924.2024.10667552

[12] Ogbolumani, O., Mabaso, B. (2023). An IoT-based hydroponic monitoring and control system for sustainable food production. Journal of Digital Food, Energy & Water Systems, 4(2). https://doi.org/10.36615/digital_food_energy_water_systems.v4i2.2873

[13] Nejatian, A., Niane, A.A., Nangia, V., Al Ahmadi, A.H., Naqbi, T.S.A.M., Ibrahim, H.Y.H., Al Dhanhani, M.A.H. (2023). Enhancing controlled environment agriculture in desert ecosystems with AC/DC hybrid solar technology. International Journal of Energy Production and Management, 8(2): 107-113. https://doi.org/10.18280/ijepm.080207

[14] Wahul, R.M., Sonawane, S., Kale, A.P., Lambture, B.D., Dudhedia, M.A. (2023). Smart Farm: Agriculture system for farmers using IoT. Ingénierie des Systèmes d’Information, 28(2): 401-407. https://doi.org/10.18280/isi.280215

[15] Akbar, M., Quraysh, Q., Borman, R.I. (2021). Otomatisasi pemupukan sayuran pada bidang hortikultura berbasis mikrokontroler Arduino. Jurnal Teknik dan Sistem Komputer, 2(2): 15-28. https://doi.org/10.33365/jtikom.v2i2.109

[16] Kondaveeti, H.K., Kumaravelu, N.K., Vanambathina, S.D., Mathe, S.E., Vappangi, S. (2021). A systematic literature review on prototyping with Arduino: Applications, challenges, advantages, and limitations. Computer Science Review, 40: 100364. https://doi.org/10.1016/j.cosrev.2021.100364

[17] Napitupulu, H.L., Ginting, R., Bellina, D.S.K. (2020). Product design of total dissolved solid. IOP Conference Series: Materials Science and Engineering, 1003: 012023. https://doi.org/10.1088/1757-899X/1003/1/012023

[18] DFROBOT, ‘Gravity Analog TDS Sensor Meter for Arduino SKU SEN0244’, https://wiki.dfrobot.com/Gravity__Analog_TDS_Sensor___Meter_For_Arduino_SKU__SEN0244, accessed on Aug. 12, 2023.

[19] Satya, T.P., Al Fauzan, M.R., Admoko, E.M.D. (2019). Sensor ultrasonik HCSR04 berbasis arduino due untuk sistem monitoring ketinggian. Jurnal Fisika Dan Aplikasinya, 15(2): 36-39. https://doi.org/10.12962/j24604682.v15i2.4393

[20] Basalamah, A., Adrian, B., Salam, F.A. (2019). Pengaturan kecepatan putaran motor DC menggunakan Arduino UNO R3 dengan tampilan LCD. Logitech Teknik Elektro, 1(2): 33-41.

[21] Pratono, A., Lubis, S.A. (2023). Rancang bangun alat pengontrolan motor dc pada Alat produksi biodiesel Dari minyak jelantah berbasis Arduino mega. TEKTONIK: Jurnal Ilmu Teknik, 1(1): 16-24. https://doi.org/10.62017/tektonik.v1i1.41

[22] Akinwole, O.O., Oladimeji, T.T. (2018). Design and implementation of Arduino microcontroller based automatic lighting control with I2c LCD display. Journal of Electrical & Electronic Systems, 7(258): 2332-0796. https://doi.org/10.4172/2332-0796.1000258

[23] Saleh, M., Haryanti, M. (2017). Rancang bangun sistem keamanan rumah menggunakan relay. Jurnal Teknologi Elektro, 8(2): 87-94. http://doi.org/10.22441/jte.v8i2.1601

[24] Soliata, F.A., Suryono, R.R. (2024). Sistem otomatisasi pengairan tanaman hidroponik berbasis NodeMCU ESP 8266. Jurnal Pepadun, 5(1): 12-19. https://doi.org/10.23960/pepadun.v5i1.198

[25] Ulum, M.B., Lutfi, M., Faizin, A. (2022). Otomatisasi pompa air menggunakan nodemcu ESP8266 berbasis Internet of Things (IOT), 6(1). https://doi.org/10.36040/jati.v6i1.4583

[26] Munthe, V.J.H., Hutabarat, M. (2023). Rancang bangun alat ukur kecepatan aliran air menggunakan water flow sensor berbasis Arduino Uno. Jurnal Teknologi Informasi dan Indutri, 3(1).

[27] Daru, A.F.F., Darmawan, H.T. (2019). Automation models turn on and turn off electric switches in accordance with the time specified using Arduino. Jurnal Pengembangan Rekayasa dan Teknologi, 15(2): 107-111. http://doi.org/10.26623/jprt.v15i2.1761

[28] Nivedan, V., Kannusamy, R. (2019). Weather monitoring system using IoT with Arduino Ethernet Shield. International Journal for Research in Applied Science & Engineering Technology, 7(1): 218-221. https://doi.org/10.22214/ijraset.2019.1038

[29] Riskiono, S.D., Pamungkas, R.H.S., Arya, Y. (2020). Rancang bangun sistem penyiraman tanaman sayur berbasis Arduino dengan sensor kelembaban tanah. Jurnal Ilmiah Mahasiswa Kendali dan Listrik, 1(1): 23-32. https://doi.org/10.33365/jimel.v1i1.186

[30] Fanani, M.R., Hariono, T. (2021). Sistem otomatis pengendali nutrisi tanaman hidroponik berbasis Arduino menggunakan sensor TDS. Exact Papers in Compilation, 3(4): 447-452. https://doi.org/10.32764/epic.v3i4.577