© 2025 The authors. This article is published by IIETA and is licensed under the CC BY 4.0 license (http://creativecommons.org/licenses/by/4.0/).

OPEN ACCESS

The agricultural sector is increasingly using various robotic systems that are characterized by diverse autonomy. Groups of drones largely ensure the implementation of sowing, harvesting, introduction of organic matter, and successful spraying of pesticides. The integration of many of the latest ground and aerial transportation equipment significantly expands the range of functional and sensor capabilities offered by robotic processing of almost any agricultural land. Therefore, this study aimed to develop a technique to calculate and select the optimal number of drones involved in agrarian land treatment, which should increase the efficiency of agricultural production. The proposed technique employs a multi-criteria structure to estimate the required number of unmanned aerial vehicles (UAVs) for cultivating a specific farm field. It can optimize the processing time and energy resources and provide cost estimation for UAVs. Testing the results of the proposed technique involved simulation modeling of UAV operations. The results showed that the proposed technique is correct, and its comparison with modeling demonstrates a high degree of convergence of the final values. The scientific novelty of this study lies in the multi-criteria calculation of the target characteristics, including considering the UAV charge using an algorithm for working with service platforms.

agricultural sector, multi-criteria evaluation, drone, robotic platform

The operation of traditional agricultural machines and mechanisms differs and involves the mandatory participation of professional operators, whose work largely depends on their skills, fatigue, and many other factors that reduce the operational efficiency and intellectual level of the agricultural sector [1-3].

Most robotic vehicles with various autonomies involved in agriculture provide seeding, fertilization, and harvesting. The combined use of multifunctional drones, which are capable of operating on the ground and in air, has expanded the range of sensory and functional capabilities of farmland cultivation. Many applications (for example, power system maintenance and air vehicle movement) require physical interaction between drones and autonomous ground-based robotic service platforms. The main difficulties of such interactions are landing, fixation, and mechanized processing of drone batteries, and it is essential to competently organize the service maintenance of drones operating as a group [4-7].

Therefore, each model and communication technique of multifunctional automated systems involved in farming is a relevant research area to improve drone operating time and reduce the time and costs of cultivating fields using specialized drones.

The farmland cultivation provided by automated systems is a complex issue, including optimal maintenance, timely recharging or refueling of robots, adjusting their operation to the current situation, and selecting the optimal number of drones. This study focuses on a method to determine the optimal number of robots for farmland cultivation and the appropriate mode of operation.

Today, global positioning and navigation, as well as the study of the specifics of the application of robotic systems in agriculture based on satellite positioning, have helped significantly expand the autonomy and functionality of the category of drones under consideration. One of the features of precision farming is the mandatory application of the latest high-tech samples to optimize all stages of agricultural production.

Literature sources describe the design processes and basic parameters and consider the performance of a new series of small agricultural robots that can perform the elementary work of a standard rural enterprise [6-10]. Robot design is an autonomous and highly mobile system that independently determines locations and generates maps or observes a specific agricultural area. As a rule, drones use artificial intelligence (AI) to produce solutions that are appropriate for current conditions. Therefore, a drone can perform a particular list of actions by considering its surrounding environment. The literature proposes the design of a relatively small agricultural drone that functions according to AI techniques and is implemented in an autonomous mobile system capable of independently determining the location and forming a map of the terrain or observing the treated areas [8]. One of the limitations of this study is that the author did not analyze the optimality of this type of robot and its efficiency in a specified agricultural area and did not conduct an economic analysis.

Over the past decade, researchers have thoroughly studied the features of technology involving automatic harvesting to increase yield and minimize manual labor. The proposed technique provides autonomous drone navigation based on visual cues and fuzzy control. In this case, a new weighting factor enables the transformation of a color image into a halftone image, which significantly improves the identification of Lycium barbarum and includes the characteristics of the minimum positive rectangle in the contour description [9]. The least-squares methodology provides the fitting of the main navigation line and the corresponding calculation of the parameters of a particular sector based on the points of each contour under consideration, thereby improving the efficiency of online systems. The design of a fuzzy controller used in pneumatic systems responsible for steering control, which should implement autonomous navigation in online mode, has been developed. The results of many experiments with a classical static image showed that, with an average operation time of 160-165 milliseconds, the level of accuracy of this technique was not less than 90%. These indicators provide high degrees of stability and performance. For example, at speeds of 1-2 kilometers per hour, the highest value of lateral deviation does not exceed 6.20-6.25 cm, and its average value generally does not exceed 2.78-2.90 cm. The design of a relatively inexpensive and energy-efficient local motion planner was proposed to optimize labor and the associated costs in field agricultural enterprises. Its function relies on the information provided by the camera, ensuring depth perception and a two-layer control methodology to realize autonomous navigation in a standard vineyard [11, 12].

Uncontrollable weather phenomena, including high winds, floods, high temperatures, drought, frost, and sandstorms, can lead to a substantial increase in operational complexity. To illustrate this point, we considered the impact of light intensity on machine vision technology. The system is particularly vulnerable to specular reflections and other forms of light pollution present on agricultural land, which can hinder the obstacle avoidance system's capacity to accurately recognize and assess obstacles owing to optical distortion and noise. In such instances, it is imperative that the machine vision obstacle avoidance technology be equipped with infrared technology to facilitate night vision [13].

In the context of agricultural operations, parameters such as flight speed and altitude exert a direct influence on factors such as droplet deposition and the efficacy of pest control measures. The configuration of these parameters is contingent on the type and growth characteristics of the plants in addition to the topographical and geographical characteristics of the terrain within the designated area of operation. Ensuring the safety of agricultural UAVs is paramount when conducting precision spraying operations at low altitudes and volumes. The complexity of the obstacle avoidance environment is further compounded by various factors, including plant protection nets, creeper support, residential buildings, green spaces, power lines and towers, communication and lighting structures, and all types of wildlife. This necessitates the development of advanced obstacle avoidance technologies to ensure the safety of agricultural UAVs. The distinct characteristics of obstacles, whether large, small, or medium in size, enable their detection by obstacle avoidance sensors within a designated safety zone, particularly when they fall within the warning or fulfilment zones. This facilitated the relatively straightforward avoidance of these obstacles by the drones. Conversely, microsized and uncharacteristic obstacles, which occupy a minute portion of the field of view, manifest randomly and irregularly. Consequently, when these obstacles enter the warning or execution zone, it remains challenging to identify and successfully avoid them [13].

When working with a group of unmanned aerial vehicles (UAVs), it is essential to consider their charge level and the recharging and movement systems of UAVs and mobile platforms. Because agricultural UAVs perform many tasks, and the cultivated land size can be large, it is necessary to provide facilities for recharging the battery of UAV and refueling UAVs with physical resources such as pesticides. There are different categories of UAVs based on various parameters, such as weight, altitude, airspeed, wing type, control system, takeoff and landing type, airspace, flight rules, and propulsion system. Battery-powered UAVs eliminate the need for nonrenewable energy sources, have a simple design, and are highly reliable, making them a primary focus of the UAV market [14].

However, the current energy management strategies used in UAVs are often immature. Thus, although hybrid power systems are relatively advanced in electric vehicles, their application in the UAV industry is still limited. By contrast, a ground base station must maintain communication for automatic battery charging or replacement. Wireless power transfer technology requires high-precision landing and wireless data transmission between the UAV and base station, which often requires a combination of battery information provided by battery management, flight control positioning, and data transmission between base stations [15-18].

Accurate estimation of the charge level during UAV flights is closely related to the flight duration, thus maximizing battery energy utilization and improving the overall flight duration. Manual battery replacement is the primary charging management method. However, studies on wireless and automated charging have been very active, particularly for large UAV fleets where charging automation is essential. Battery management systems for UAVs should consider the most appropriate automatic charging methods for their application scenarios [19].

Information technology plays a significant role in sustainable development. The application of the Internet of Things (IoT) in agriculture is a modern solution based on the latest advances in communication, computing (Internet, cloud computing, big data, and business intelligence), and sensor technologies (smart sensors and actuators). IoT has been studied more intensively, and agricultural application possibilities and specific solutions are becoming increasingly numerous [20, 21].

Adopting an intelligent sensor network offers undeniable advantages such as new network IoT devices, reliability or fault tolerance, flexibility (a fixed architecture of the sensor network), and low energy consumption. The use of an IoT device network has not yet become a standard practice in the agro-industrial context; specific solutions have only appeared in small experimental plots and greenhouses. The most common reason for the limited application of IoT networks is their fixed location and many sensors, which entail high investment costs, particularly in large areas. Mobile robots and UAVs have been proposed as replacements for intelligent sensor networks in greenhouses [22-24].

UAVs are the only alternative to IoT networks for collecting and analyzing data in confined areas. The literature offers several solutions to the problem of selecting an optimal UAV for particular user criteria. For example, existing software makes it possible to calculate the most suitable UAV based on its weight, price, loading, control, and other criteria [25].

Battery state estimation algorithms used in current UAV applications are often simple, and most intelligent algorithms are still in the modeling stage without being implemented during flights. In the future, remote processing and analysis of collected data through cloud storage and network communications may provide more accurate state estimation, thereby improving safety and reliability.

A primary trend in communication and data storage is the use of networks and their integration into cloud platforms. However, real-time and delay-free data transmission and processing remains challenging. In addition, ensuring the security of the data-transfer process is of utmost importance.

Studies on UAV battery management fault diagnosis are still relatively limited because this field is comparatively new and lacks a comprehensive knowledge system. Future efforts may focus on collecting relevant historical data and expert opinions combined with data-driven fault prediction and diagnosis algorithms.

The development of agriculture, according to the 4.0 model, implies the application of such tools as sensors, specialized information systems, improved machinery, and, of course, the principles of informed management. Practice shows that using such tools increases the efficiency of production, based on the calculation of specific arguments and the uncertainty that occurs in almost any agricultural system. Using robotic autonomous systems capable of working on the ground and in air significantly optimizes the solutions of many agricultural problems and reduces the duration of their implementation. For example, the combined use of ground- and aerial-based devices holds great promise for ensuring the accurate and highly efficient execution of almost any field operation [26].

Classical route planning involves a clear division of navigation tasks, reduced to global planning and then to local planning. Thus, global route planners ensure the generation of a local goal (i.e., each waypoint in the route), whereas local planners are responsible for generating a smooth and accessible main route. As global route planners are responsible for identifying targets based on previously established grids/maps that show the occupancy of each intermediate field regarding the initial and desired configurations, global planning typically applies graph search principles or builds a route based on particular selections. By contrast, a planner relying on interpolating curves usually plays the role of a local planner [27-30].

The interaction of a group of drones with hybrid robotic systems can solve several complex tasks. This principle, which has been realized in many practical applications, has demonstrated a high efficiency. In the agricultural field, where work is performed by autonomous ground and aerial drones that form a map, report the current location, and crop growth features, navigation focuses on obstacle avoidance and automatic localization of objects of interest (for example, fruits and trunks), which considerably simplifies the use of appropriate tools. However, the availability of limited computational resources in relatively inexpensive commercial or experimental autonomous vehicles and unequal speeds depending on the specificity of operation (for example, a vineyard or a land plot located on a slope) does not always allow simultaneous online automatic localization and mapping [31, 32].

Drones acting as groups parallel to rows of grapevines use highly specialized spraying systems to build a correct and highly efficient pattern of agrochemical distribution to crops, minimize spray drift, and reduce associated costs. A group of drones treats only the upper part of the vines to distribute the product evenly. Accordingly, this reduces the drift level dispersion, and the application becomes as uniform as possible [33, 34]. However, these studies did not consider the optimal number of UAVs for the treatment.

Few researchers have addressed the problem of organizing the production of multiple UAVs in an agricultural area using multi-criteria analysis of particular criteria, such as UAV energy state, processing time (speed), and total equipment cost. Therefore, it is necessary to develop a method of interaction between UAVs that can reduce the time and resources required to process a particular agricultural field using multi-criteria processing.

The structure of an agricultural area can be described by the following base characteristics: geometric passability of ground technical systems within the cultivated area, parameters of the growing crop, agrarian tasks with a sequence of actions for implementation, and meteorological conditions [35, 36].

Figure 1 shows the flowchart diagram developed to describe the sequence of further work.

Figure 1. Flowchart diagram of the problem study and development process

To formalize the interaction between the participants of the agricultural heterogeneous robotic complex and ensure the dispatching of drone maintenance by ground-based service platforms, the authors propose a scheme consisting of an agricultural area, drone, service platform, and ground center providing coordination. This scheme is a framework for coordinating and sharing a service platform located on the ground with a group of drones used in agriculture.

The proposed technique requires a coordinating center based on the ground that ensures the interconnection of all involved heterogeneous robotic systems, plots their trajectories, and plans methods for solving tasks. The structure of the coordinating center assumes the presence of an automated shift operator. However, enhancing drones and their interactions increases their autonomy and eventually provides supervisory control and monitoring in abnormal situations.

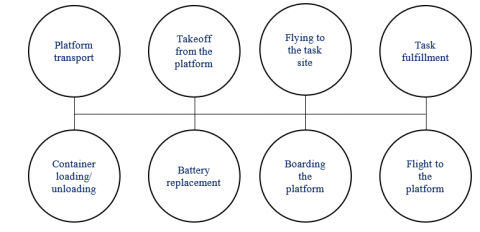

The functioning of ground-based service platforms includes the following characteristics: their operation modes, list of coordinates, speed, states of systems that provide drone power supply, filling of containers with working substances, and the number of drones serviced by the platform. Figure 2 shows the base components and their interrelationships as conceptually defined by the authors of this study.

Figure 2. Conceptual representation of the complex correcting heterogeneous robotic system used in agriculture

A formalized model for coordinating the interaction of each heterogeneous agricultural robotic system in the complex, as presented below, was developed to analyze the obtained results. Suppose that the work occurs in agricultural area S, which is described by the following characteristics.

$S=<H, O, G, C>$

Here, $H=\left(h_1, h_2, \ldots, h_i, \ldots, h_I\right)$ is the total of all the plots of cultivated land.

$O=\left(o_1, o_2, \ldots, o_j, \ldots, o_J\right)$ are objects that provide processing.

$G=\left(g_1, g_2, \ldots, g_l, \ldots, g_L\right)$ are all facilities in which the robotic devices are based and stored.

$C=\left(c_1, c_2, \ldots, c_k, \ldots, c_K\right), C=$ represents all crops grown.

In addition, $U=\left(u_1, u_2, \ldots, u_m, \ldots, o_M\right)$ is a group of drones and $P=\left(p_1, p_2, \ldots, p_n, \ldots, p_N\right)$ are service platforms operating at a given location.

Let us apply such characteristics to describe the current state of the drone $u_i$:

$u_i=<C_i, V_i, E_i, T_i, f_i>$

Here, $C_i$ - a list of current drone coordinates, $V_i$ - current drone speeds, $E_i$ - a drone battery charge level, $T_i$ - the duration of drone stay in the air, and $f_i$ - selected robot operation modes.

Let us use the following characteristics to describe the current state of non-land-based service platforms $p_j$:

$p_j=<C_j, V_j, E_j, N_j, f_j>$

Here, $C_j$ - a list of current drone coordinates, $V_j$ - current drone speeds, $E_j$ - a current energy status of the platforms, $N_j$ - the number of drones serviced by the platform, and $f_i-\mathrm{a}$ current mode of the platform functioning.

Formally, the problem is reduced to a scheme that provides model algorithmic coordination and interaction of a group of drones $U$ with a set of ground-based service platforms $P$. This scheme should provide service to working location $S$ considering resource constraints $L$, including a given number of robots, limited water and mineral resources, the workload of each processing facility, a safe route for drone movement, and many other factors.

The structure of technical equipment of ground-based service platforms includes:

1) A system controlling all components of the platform (a module responsible for interaction and navigation, a module providing power supply to the robots, a set of sensors, and a module coordinating all embedded technical systems.

2) The drone service system includes a module for take-off/landing, orientation in space, monitoring of the charge of the drone battery, and loading/unloading of a working substance (for example, pesticides and fertilizers).

Currently, a particular functionality realized by mobile platforms has been developed, and its design features are expressed as follows.

$F=\left\{f_1, f_2, f_3, \ldots, f_8\right\}$

Here, $f_1$-movement of platforms: 1) movement from the starting point to the work site and back, 2) movement within the agricultural area to solve the current task; $f_2$ - battery charge level realized by: 1) contact connection of the battery of the drone directly to the platform; 2) replacement of the battery of the drone; 3 ) wireless charging of the battery; $f_3-$ order of contact interaction between platforms and a group of drones, including docking of each drone to a platform, drone movement within platforms, takeoff/landing; $f_4$ - degree of robot loading with working substances from the corresponding platform containers; $f_5$ - cargo receipt (harvested crops or stones from clearing a land plot) from the drone; $f_6-$ interconnection of mobile platforms with a group (groups) of drones and the primary station; $f_7$ - navigation of mobile platforms considering the specifics of the global spatial orientation system using heterogeneous sensors; $f_8$ - the coordination of steps taken during the planning and actions of mobile platforms interacting with a group of drones.

The specificity of the created concept series of robotic platforms is that the platform has parking spaces for several drones simultaneously. Platform design includes the following components:

1) A running gear that enables the platforms to move within an agricultural location;

2) A multi-sensor system that detects local obstacles during the movement of the platforms;

3) A power supply system that provides electricity to the platform and all drones;

4) A navigation system that monitors the movement of the platforms from the starting point to a given point (global navigation), and a local system deployed at a given location before the start of the main work;

5) A communication system providing interconnection of mobile platforms, drones, and the primary station;

6) A body with parking spaces for drones and containers with working substance.

To operate the developed algorithm, it was necessary to consider the structural model of the interaction of the robotic systems presented in Figure 3.

Figure 4 shows an external view of the functional model of the platform, its functionality in performing an autonomous agricultural mission, and the interaction of robots during the processing of a rural object. Using the communication system, each member of the drone group reports the following characteristics to the ground station: maximum duration of operation, current charge of the battery(s), and coordinates of the current location. Simultaneously, the drone received a list of coordinates for the current positions of the ground stations and their readiness to serve the drone under consideration.

When the battery of the drone is low or the built-in container with a working substance (for example, pesticides) needs refueling, the drone generates a landing request. After receiving permission, the robot lands on the parking space of the service platform, and the module that corrects the landing of the drone ensures the fulfilment of all the landing steps.

The capabilities of the communication system ensure data exchange between the robot and platform, considering the current drone location, station location, current drone battery charge, and maintenance requirements. The platform, based on the ground, has a special compartment (for fertilizers or other payloads) and a docking point where the drone lands, if necessary. The docking points consist of a system that monitors the landing of the robot, a system that provides the spatial orientation and blocking of the drone, a device that recharges/replaces the battery of the drone, and a system that monitors the readiness of the robot to takeoff.

A landing point with a size of approximately 75 cm provides service for drones with landing slots of up to half a metre. Blocking and fixation systems are located along the contours of service platforms, ensuring their timely opening through hydraulic lifting mechanisms. The system that monitors the robot landing checks each step of the landing action and confirms whether the drone has landed. Furthermore, it ensures the transmission of characteristics such as the coordinates of the current location of the drone to the module, correcting the platform operations.

The drone fixation and blocking module receives a signal confirming the drone landing, which is necessary to correct the operation of the spatial orientation module and the module blocking the robot body on the landing site, and unblocking the drone after it receives confirmation for the drone takeoff.

Figure 3. External view of the structural diagram, which ensures the interaction of each agricultural heterogeneous robotic system operating as part of the complex

Figure 4. External view of the standard model of mobile platform functioning

The system responsible for the readiness of the robot for takeoff receives information about the current battery charge and the main goals of the upcoming mission and sends the corrective information to other modules of the platform.

The module that monitors the battery of the drone charging/replacement receives a corresponding signal, confirming that the drone group member has landed, after which battery recharging/replacement begins, followed by data transmission on the remaining battery charge.

The module that monitors the landing of the robot generates a signal confirming the landing of the drone if it has completed all the landing steps on the service site. These data are transmitted to the module that provides the spatial orientation, and to the blocking module that fixes the drone in the relevant position at the appropriate location. The module that monitors the readiness of the drone for takeoff checks the battery charge, and then sends a corresponding signal to the battery charging/replacing module. It happens until the module monitoring the readiness of the drone for takeoff receives confirmation from the module of the readiness of the drone for takeoff that the battery is fully or partially charged. The module controlling the readiness of the drone for takeoff received a signal regarding the main tasks of the upcoming mission. After confirming that the drone is ready for takeoff, the module that blocks the body of the drone receives the corresponding signal, after which it unblocks. When the drone takes off, the module monitoring the landing generates a signal confirming a successful takeoff and a signal that the site has a free place for the next drone to land.

The specificity of the spatial orientation of drones connected to the power-supply module of service platforms is of particular interest. The robot battery was held at a certain position. The drone requires fixation immediately after landing to interact with the battery. This study assumes that the service platform is in an open area; therefore, weather conditions make accurate landing difficult. Therefore, we focused on the spatial robot orientation after landing with insignificant errors. The modules correcting the flight of the drone may allow tolerable errors explained by weather conditions and small inaccuracies of the previously plotted route. In this case, the task complexity is due to moving the robot from the erroneously calculated route point to the landing position, that is, to the battery replacement area.

The module that holds the battery pack in the drone body has relatively low weight. In addition, it should guarantee reliable battery retention during missions of varying complexities by withstanding shocks, keeping the electrical contacts of the drone battery closed, and providing an easy option for battery installation and removal. The module design includes a body equipped with elastic-angled latches to lock the battery securely. At the moment of actuation, each latch bends, allowing the battery to move freely owing to the series of notches on the battery housing, making it possible for the latches to lock the battery securely. Now, let us consider the maintenance of drones located in platform parking spaces.

Considering the almost continuous improvement in the service station design that provides contactless charging or replacement of the robot battery, we modeled the process of interaction between a group of drones and robotic service platforms based on the ground. The drone goes to a specified platform site when the battery is low. Next, the robot was serviced based on the current battery charge. Upon receiving a signal from the drone regarding the need to charge its battery, the service platform sends drone data, confirming the availability of a parking space for service. Upon receipt of the corresponding signal, the drone lands with acceptable errors were automatically eliminated by the module responsible for spatial orientation.

After completing all landing steps, the module orients the drone in a predetermined position and securely blocks the drone. Next, the battery is automatically removed from the drone, charged, and then the fully charged battery is fixed in the body of the drone. Once this process was complete, the robot was undocked and removed.

When the drone $u_i$ interacts with the corresponding modules of platform $p_n$, service $Q\left(u_j\right)$ in agricultural space $S$ includes charging the battery of the drone $e^{u_m}$ or filling the containers with the working substance $r^{u_m}$.

$Q\left(u_m\right)=f\left(e^{u_m}, r^{u_m}, p_j, S\right)$

Let us investigate robot services from the perspective of a mass maintenance system (MMS) [37, 38]. All ground-based service platforms represent a multichannel complex with the number of channels equal to the number of parking spaces. Let us consider a list of possible variations of using traditional MMS [39]. Figure 5 shows the algorithmic model of the service platform functioning, which provides power to drone batteries while implementing target agricultural tasks. In the first process, the current charge of the drone battery is monitored.

The system functionality, with the option of waiting by the drone for free landing space, implies that the robot must land to wait to complete all activities to service other drones by the platform under consideration. In our situation, with several stations, the MMS variant under consideration is inefficient because these platforms may service the robot.

Failure of the system functionality (if there are no available landing places for servicing the robot) implies the selection of other platforms with free sites. Because service platforms, in addition to servicing drones, also transport them, the number of robots involved cannot exceed the total number of parking spaces in the list of stations. Considering the MMS categorization, it is necessary to consider the limited number of robots allowed for service by closed systems. Therefore, for the timely service of any drone during station identification, it is essential to consider the distance from the station, degree of congestion, and limited resource base of the functioning platforms. Additionally, each service platform is homogeneous; therefore, an MMS with parallel channels should be used.

During drone battery maintenance, the charged batteries move to the containers of the drones and the old batteries move to the appropriate cells in the service station. When applying fertilizer, drones can refill their containers with the working substances available on the platform. When harvesting crops, drones unload their containers into larger containers.

The module for charging the battery of the drone removes it from the body of the drone after the orientation of the drone in space and landing. Next, the battery moves to the battery-replacing space and the fully charged battery sits in the drone body with the following preparation and subsequent takeoff activities.

Figure 5. Schematic representation of the technique for maintenance of drones by ground-based service platforms

Figure 6 displays the basic robot operating options and several possible transitions during agricultural missions. The simulation uses an MMS with heterogeneous nodes; however, we assume that their docking mechanisms are multipurpose systems and that the landing places can be busy with robots to change a battery or to service a container with the working substance. Robot maintenance by service platforms includes sequential mutual exchange of physical and energy resources, as shown in Figure 7. After all the service activities, the robot connects to one of the resource containers to fill the containers of the drones with the working substance. This mode provides significant time and energy savings for moving the robot from a land plot with the following takeoff and landing operations.

Therefore, it is an approximately closed multichannel and multiphase MMS with heterogeneous nodes. The study of the regularities found in the distribution of time intervals separating the requests arriving at the electronic complex and the regularities determining the distribution of the processing of each request have shown that the created concept shows the presence of a Poisson incoming flow and a deterministic distribution of the duration of service activities. Using the notation proposed by Kendall, MMS patterns can be expressed as M/D/n/n.

In solving specific agricultural tasks, in addition to all the activities related to battery maintenance, drones must refill a working substance, such as pesticides, or transfer harvested crops. For this purpose, the platform has an inbuilt container that sends a certain mass of working substance to the robot during maintenance. A ground service platform was selected if the drone required service. For this purpose, the availability was analyzed, and the resource base of the platforms was evaluated (to charge the battery or to refill the container with the working substance). A platform without a sufficient working substance (charge) can only land a drone that can then return to the primary station.

After battery charging and replacement, loading, or unloading from the respective platforms, the robot signals that it will be ready for the next mission. If resources on the respective platforms are absent, the drones land on the nearest platforms and switch to transport mode. If the drone sprays all working substances or achieves all targets, it takes the transport position, and the service platforms move to the base centers.

Figure 8 shows an external view of the algorithmic model that corrects the operation of a drone in an agricultural field. If the battery is low and the container is empty or full, the drone searches for the nearest platform or checks for free parking space. When there are free parking spaces, the drone assesses the energy resources of the site (if the battery needs charging/replacement) or the working substance resources of the site (if the drone needs loading/unloading of working substances).

Figure 6. List of probable states of drone operation

Figure 7. Drone maintenance in the energy and working substance exchange process

Figure 8. External view of the algorithmic model, which corrects the operation of the drone to maintain it by service platforms

Let us logically describe the principles of the algorithmic model, which aims to determine the current state of drones and service platforms when cultivating a plot of land. At the initial stage, the model checks the current cultivated area $s_t{ }^oj$ and the functioning of the robots, and the service platform operation stops when the cultivation of the considered plot is complete $s_t^{o_j}=s_{\max }^{o_j}$. The functioning of individual platforms also stops when their physical $r_t^{p_n}<r_{\text {max }}^U$ or energy $e_t^{p_n}<$ $e_{\min }^{p_{\text {max }}^U}$ resources are at minimum. In such a situation, all robots should land the parking spaces, and the station itself starts to move to the location of the central base.

When performing a basic agricultural task in the field, the battery charge of the drone $e_t^{u_m}$ and the current volume of its container $r_t^{u_m}$ are checked. If the battery charge of the drone is lower or corresponds to the minimum charge $e_t^{u_m} \leq$ $e_{\text {min }}^u$ required to return to the station, or if the working substance containers $r_t^{u_m}=0$ are empty, the drone moves to the platform for servicing.

To correctly estimate the required number of robots that can cultivate a particular agricultural plot, we propose using the following characteristics.

1) Total cultivation time $t^{s u m}$;

2) Total energy consumed $e^{s u m}$;

3) The total cost of the drones used $c^{\text {sum }}$.

In calculating the total cultivation time $t^{\text {sum }}$, we assume that some service platforms and nearby drones are simultaneously traveling to the farmland. Therefore, the majority of the time cost is spent on moving a notional platform to and from the land plot, and it is essential to consider the duration $t^{\circ}$ of cultivation of a particular plot and the maintenance time $t^u$ of the robots:

$t^{\text {sum }}=2 t^{C P}+t^o+t^u$

Here, $t^{\circ}=\frac{s^o}{\Delta s n m}$ is the average period of operation of all the involved drones at a particular agricultural location, $n \in(0, N]$ is the number of drones, and $n \in(0, M]$ is the number of stations. Calculating the time spent on robot maintenance requires setting the time interval $t^{\circ}$, during which the drone receives energy and physical resources:

$t^u=\frac{t^o}{r_{\max }^U{ }^{P S^u}{ }_p \frac{t^o}{e_{\max }^U{ }^{P S^u}{ }_p}}$

In that case:

$\begin{align} & {{t}^{sum}}=2{{t}^{CP}}+\frac{{{s}^{0}}}{\Delta snm}+\frac{\frac{{{s}^{0}}}{\Delta snm}}{r_{\max }^{U}\Delta t}(2{{t}^{PS}}+t_{p}^{u})+\frac{\frac{{{s}^{0}}}{\Delta snm}}{e_{\max }^{U}\Delta t}(2{{t}^{PS}}+t_{p}^{u})= \\ & =2{{t}^{CP}}+\frac{{{s}^{0}}}{\Delta snm}+\frac{{{s}^{0}}}{\Delta snmr_{\max }^{U}\Delta t}(2{{t}^{PS}}+t_{p}^{u})+\frac{{{s}^{0}}}{\Delta snme_{\max }^{U}\Delta t}(2{{t}^{PS}}+t_{p}^{u}) \\\end{align}$

In the context of replenishing the resources of UAV, it is imperative to consider the rate of charging and the rate of filling with physical resources. In this study, the maximum values of these parameters are denoted as $e_{\max}^u$ and $r_{\text {max}}^u$, respectively, and the total amount of time spent on UAV maintenance is denoted as $t_{\max }^u$. These parameters directly affect the efficiency of agricultural field-processing systems.

When calculating the total energy resources required to process a particular area O, it is essential to consider the movement of the stations from and back to the central bases, and the time interval necessary to maintain the batteries of each robot during its operation:

$e^{\text{sum}} = n 2 e_{\min}^{P \frac{s^o}{{\Delta \operatorname{snme^U}_{\max}}_{\min}^{P \frac{s^o}{\Delta s e_{\max}^U}}}}$

The total cost of the machinery involved must consider the cost of maintaining the platform and each serviced robot:

$c^{\text {sum }}=n c^P+m c^U$

An improvement in the aforementioned relationships was made to minimize the impact of negative factors.

$t_U^r=r_{\max }^{U \frac{\Delta t}{\Delta r}}$ is the time during which the physical resource of the drone is minimal.

$t_U^e=\left(e_{\max }^{U_{\min }^{U \frac{\Delta t}{\Delta e}}}\right)$ is the time during which the energy resource of the drone is minimal.

Considering the consumption of the total resource base, the time interval for cultivating the field and the energy consumed are calculated as follows:

$\left\{ \begin{align} & {{t}^{sum}}=2{{t}^{CP}}+\frac{s_{\max }^{{{o}_{j}}}\Delta t}{nmr_{\max }^{U}\Delta t}\left( 2{{t}^{PS}}+t_{P}^{u}+\frac{r_{\max }^{U}\Delta t}{\Delta r} \right) \\ & {{e}^{sum}}=n2e_{\min }^{P}+\frac{s_{\max }^{{{o}_{j}}}\Delta r}{r_{\max }^{U}\Delta t}\left( 2{{t}^{PS}}+\frac{r_{\max }^{U}\Delta t}{\Delta r} \right)\Delta e \\ & {{t}^{sum}}=2{{t}^{CP}}+\frac{s_{\max }^{{{o}_{j}}}\Delta e}{nm(e_{\min }^{U}-2e_{\min }^{U})\Delta t}\left( t_{P}^{u}+\frac{e_{\max }^{U}\Delta t}{\Delta e} \right) \\ & {{e}^{sum}}=n2e_{\min }^{P}+\frac{s_{\max }^{{{o}_{j}}}\Delta e}{(e_{\min }^{U}-2e_{\min }^{U})\Delta t}e_{\max }^{U} \\\end{align} \right.$

When $t_U^r<t_U^e$, the volume of physical resources decreases faster than the energy. When $t_U^r=t_U^e$, the consumption of the physical and energy resources is parallel to $r_{\max }^{U \frac{\Delta t}{\Delta r}}\left|\left(e_{\max }^{U_{\min }^U}\right) \frac{\Delta t}{\Delta e}\right|$. Therefore, it is possible to optimize the indicator describing the amount of energy resources required for one takeoff, thereby minimizing the cumulative number of takeoffs required to solve the tasks in a particular mission.

The multi-criteria evaluation required to make decisions regarding the necessary number of robots is a linear combination of the previously discussed values:

$\varepsilon\left(S^o, n, m\right)=t^{\text {sum }} w_t+e^{s u m} w_e+c^{\text {sum }} w_c$

Here, $w_t, w_e, w_c$ are a list of weighting indicators that describe the prioritization of time, energy, and economics. The weights are responsible for prioritizing a particular parameter in the calculation and can be varied according to the requirements based on the output parameters obtained in the calculation. This adaptable system facilitates the attainment of the requisite values when priorities are defined. By categorizing the values required for the multi-criteria evaluation, values describing the number of stations and drones for a specific land $e^{o p t}$ were selected:

$\operatorname{Arg} \min _{n \in N, m \in M}\left(\varepsilon\left(S^o, n, m\right)\right)=<n^*, m^*>$

The weight of each component is selected according to the expressions:

$w_t=3, w_e=1, w_c=1$ – if the priority is to reduce the processing time;

$w_t=1, w_e=2, w_c=3$ – if the priority is to reduce the processing costs.

Given the small number of characteristics and low complexity of the calculations, the proposed technique relies on a complete enumeration of variations in the number of drones and service stations involved in agricultural operations.

Figure 9. Technique to calculate and select the optimal number of processing drones

The technique shown in Figure 9 is a schematic representation of modeling and the subsequent determination of the number of robots. An evaluation of the advantages of the proposed algorithm in calculating the required number of drones shows that it is essential to consider the effectiveness of the proposed criteria. Because of the multi-criteria evaluation, it was possible to determine the number of robots necessary to cultivate a specific plot of land, considering the combination of values representing the weights, that is, $w_t, w_e, w_c$ = (one, one, one). Figure 10 displays a function describing the multi-criteria evaluation of the required number of drones, given equal weights, and an optimal platform/drone ratio of 1/4. Accordingly, when considering weights, the essential criterion should have the highest value. The obtained results were compared with the modeling results to assess the accuracy of the proposed technique for calculating the optimal drone number. Figure 11 shows the results of the comparison.

Figure 10. External view of the multi-criteria evaluation of the required number of drones

Figure 11. Comparison of calculated values with the list of simulation parameters

The results of separate experiments demonstrate the presence of certain discrepancies in the values calculated in the last flight, considering that the processing of the field is complete, and the drone goes to the station with a set of unspent resources. This suggests that refueling and filling the containers of drones with working substances should occur in parallel.

Numerous drones have been successfully used in the agricultural sector to monitor land, generate maps, analyze crop yields, and plan the application of mineral substances and pesticides. Today, we observe the emergence of new prototypes that physically interact with many surrounding objects, which naturally suggest the consumption of large amounts of energy. Owing to the interaction of drones functioning on the ground and in the air, it was possible to significantly increase the duration of the autonomous operation of these categories when performing missions of varying complexity.

This study analyzed investigations related to the behavior of UAVs in agriculture, including recharging UAVs using various methods [15, 16]. The current investigation closes definite gaps in the literature by presenting a method for operating UAVs with charging platforms, by algorithmizing the charging process while working with a group of drones.

A simulation program was developed for utilization across diverse agricultural terrains. During the experimental process, data pertaining to diverse field sizes were analyzed, and the results indicated no discrepancy in performance [40].

It is imperative to acknowledge that inclement weather conditions present considerable challenges for the autonomous navigation of agricultural Unmanned Aerial Vehicles. Strong winds have been shown to have the potential to destabilize UAVs, resulting in deviations from planned flight paths and an elevated risk of collision. Rainfall introduces moisture, which can interfere with onboard electronics and sensors, causing malfunctions or failures. Fog and low-visibility conditions have been shown to impair the ability of UAVs to detect and avoid obstacles, thereby compromising their operational safety. Furthermore, certain weather phenomena, such as thunderstorms, can cause electromagnetic interference, disrupting the communication between the UAV and its control systems, leading to potential loss of control. To address the aforementioned issues, it is imperative that UAV launches consider prevailing weather conditions during both the takeoff and operational phases [41].

The prevailing trend in the domains of communication and data storage is towards the utilization of networks and their integration with cloud platforms. Nevertheless, the challenge of achieving real-time data transmission and processing without delay persists. Ensuring the security of the communication process is of utmost importance [42].

It has been demonstrated that, given that the system under scrutiny can accommodate expansion without compromising efficiency, an augmentation of the working space, that is, an increase in field size, is not expected to engender a decline in efficiency. In conclusion, the proposed method is deemed a suitable tool for scaling up and application in large-scale agricultural projects. It is predicted to provide resource optimization and improve the efficiency of agricultural operations. The presented algorithms have the capacity for straightforward adaptation and scaling to accommodate a variety of decision-making problems, thus engendering flexibility and wide applicability. Multi-criteria decision-making methods are effective tools for solving complex decision-making problems. A number of key advantages, including a structured approach, versatility of application, and ability to effectively handle both qualitative and quantitative information [43], characterize the utilization of multi-criteria decision-making methodologies.

Recent scientific investigations in the field of UAV optimization for agricultural applications have highlighted the efficacy of evolutionary algorithms, specifically Genetic Algorithms (GA) and Particle Swarm Optimization (PSO), in addressing complex path planning and resource allocation challenges. Research indicates that GAs, which emulate natural selection mechanisms such as selection, crossover, and mutation, offer robust global search capabilities while maintaining diversity in candidate solutions to avoid local optima in non-linear and multimodal agricultural environments. Conversely, PSO exhibits rapid and efficient convergence by dynamically updating candidate positions based on individual experience and social learning, rendering it particularly effective for continuous optimization problems, such as UAV trajectory planning [44]. However, when UAVs operate in precision agriculture, they must balance multiple conflicting objectives including fuel efficiency, area coverage, obstacle avoidance, and real-time data acquisition. In such scenarios, multi-criteria evaluation (MCE) techniques have been shown to excel, as they integrate diverse performance metrics into a unified framework for holistic route assessment, enabling decision-makers to prioritize critical factors via weighted evaluation schemes.

Many studies have addressed the problem of UAV groups operating on agricultural sites. Several methods have been proposed to optimize the performance of UAVs when processing rural sites. Such methods often describe the calculation of the optimal UAV movement strategy and its operation with different heterogeneous ground systems, considering the problem of optimal loading of UAVs with various types of resources. The purpose is to optimize the process [45]. The proposed technique makes it possible to determine the optimal parameters for the number of vehicles for cultivation of an agricultural field and to select the priority direction for optimization.

6.1 Scientific novelty

The novelty of the proposed technique for analyzing the required number of drones for farmland cultivation lies in the multi-criteria evaluation using a linear combination of parameters, such as the total duration of cultivation, electricity consumption, and the cost of applied drones. The proposed technique makes it possible to model and optimize the number of drones used in autonomous mode.

The creation of models and techniques capable of adjusting the work of agricultural multifunctional mechanisms in interaction with robotic platforms has made it possible to optimize the performance of specific tasks, namely, to replace the battery in a minimum time and move various cargoes. The optimization of the time spent on the maintenance of service platforms for drones made it possible to reduce the duration of recharging their batteries and increase the duration of autonomous operation.

6.2 Theoretical contributions

The developed multi-criteria model of the interaction between heterogeneous systems and UAVs makes it possible to expand our understanding of the interaction between drone architectures and heterogeneous devices. The proposed algorithm helps understand the possibilities of using such systems in agriculture and presents possible methods for farmland processing.

6.3 Practical implications

The developed multi-criteria model of the interaction between heterogeneous systems and UAVs makes it possible to expand the understanding of the interaction between drone architectures and heterogeneous devices. The proposed algorithm provides a better understanding of the possibilities of using such systems in agriculture, and presents possible methods for farmland processing.

6.4 Research limitations

However, this technique also has several limitations. An analysis of these methods implies the application of multirotor UAVs, as they are the most common choice for the task considered in this study. However, this technique cannot work with the same efficiency as that of airplane-type UAVs. The developed methodology is intended for the cultivation of agricultural land in open spaces and has not yet been subjected to real-world testing under conditions such as wind, fog, or inclement weather. To ensure the effectiveness of the methodology, it is necessary to conduct trials in fields with different sizes. It is important to take into account the fact that the geological structure of the field can significantly affect the optimality of the routes and the overall treatment time. Conducting such trials will facilitate the adaptation of the methodology to a range of conditions, thereby enhancing its practical applicability in agricultural contexts but is intended to treat agricultural land in an open space.

6.5 Future research directions

In further research on this topic, the proposed technique should be verified and supplemented by calculations for all types of modern UAVs used in agriculture. It is also necessary to improve the proposed technique by considering environmental parameters, thus creating an even more versatile algorithm for the optimal operation of agricultural UAVs and their interactions with heterogeneous devices. In subsequent studies, it is envisaged that the proposed methodology will be subjected to empirical testing in real-world scenarios, with conditions that incorporate a variety of parameters such as weather, field volume and its characteristics, objects with which collisions are possible, and so forth.

Some results of this research were obtained as part of the work under the Subsidy Agreement dated July 14, 2023 No. 075-15-2023-599 on the topic: “Development of intelligent, high-precision tools for analyzing terrain and managing transport systems intended for highly productive agriculture” with the Ministry of Science and Higher Education of the Russian Federation.

[1] Millard, A.G., Ravikanna, R., Groß, R., Chesmore, D. (2019). Towards a swarm robotic system for autonomous cereal harvesting. In Lecture Notes in Computer Science, Springer, Cham. pp. 458-461. https://doi.org/10.1007/978-3-030-25332-5_40

[2] Avellar, G., Pereira, G., Pimenta, L., Iscold, P. (2015). Multi-UAV routing for area coverage and remote sensing with minimum time. Sensors, 15(11): 27783-27803. https://doi.org/10.3390/s151127783

[3] Alexandrov, I.A., Mikhailov, M.S., Muranov, A.N., Kuklin, V.Z. (2024). Recognition and classification of 3D objects of different details. Qubahan Academic Journal, 4(2): 529-539. https://doi.org/10.48161/qaj.v4n2a557

[4] Tamirat, T.W., Pedersen, S.M., Ørum, J.E., Holm, S.H. (2022). Multi-stakeholder perspectives on field crop robots: Lessons from four case areas in Europe. Smart Agricultural Technology, 4: 100143. https://doi.org/10.1016/j.atech.2022.100143

[5] Lei, Z., Zhou, H., Hu, W., Liu, G. (2021). Unified and flexible online experimental framework for control engineering education. IEEE Transactions on Industrial Electronics, 69(1): 835-844. https://doi.org/10.1109/tie.2021.3053903

[6] Radoglou-Grammatikis, P., Sarigiannidis, P., Lagkas, T., Moscholios, I. (2020). A compilation of UAV applications for precision agriculture. Computer Networks, 172: 107148. https://doi.org/10.1016/j.comnet.2020.107148

[7] Tatarkanov, A.A., Alexandrov, I.A., Chervjakov, L.M., Karlova, T.V. (2022). A fuzzy approach to the synthesis of cognitive maps for modeling decision making in complex systems. Emerging Science Journal, 6(2): 368-381. https://doi.org/10.28991/esj-2022-06-02-012

[8] Beloev, I., Kinaneva, D., Georgiev, G., Hristov, G., Zahariev, P. (2021). Artificial intelligence-driven autonomous robot for precision agriculture. Acta Technologica Agriculturae, 24(1): 48-54. https://doi.org/10.2478/ata-2021-0008

[9] Tatarkanov, A., Alexandrov, I., Muranov, A., Lampezhev, A. (2022). Development of a technique for the spectral description of curves of complex shape for problems of object classification. Emerging Science Journal, 6(6): 1455-1475. https://doi.org/10.28991/esj-2022-06-06-015

[10] Alexandrov, I.A., Kuklin, V.Z., Muranov, A.N., Polezhaev, D.V. (2024). Developing an algorithm for Real-Time 3D identification of images. Engineering Journal, 28(5): 83-94. https://doi.org/10.4186/ej.2024.28.5.83

[11] Ma, Y., Zhang, W., Qureshi, W.S., Gao, C., Zhang, C., Li, W. (2020). Autonomous navigation for a wolfberry picking robot using visual cues and fuzzy control. Information Processing in Agriculture, 8(1): 15-26. https://doi.org/10.1016/j.inpa.2020.04.005

[12] Alexandrov, I.A., Kirichek, A.V., Kuklin, V.Z., Chervyakov, L.M. (2023). Development of an algorithm for multicriteria optimization of deep learning neural networks. HighTech and Innovation Journal, 4(1): 157-173. https://doi.org/10.28991/hij-2023-04-01-011

[13] Islam, N., Rashid, M.M., Pasandideh, F., Ray, B., Moore, S., Kadel, R. (2021). A review of applications and communication technologies for Internet of Things (IoT) and Unmanned Aerial Vehicle (UAV) based sustainable smart farming. Sustainability, 13(4): 1821. https://doi.org/10.3390/su13041821

[14] Xie, Y., Savvarisal, A., Tsourdos, A., Zhang, D., Gu, J. (2020). Review of hybrid electric powered aircraft, its conceptual design and energy management methodologies. Chinese Journal of Aeronautics, 34(4): 432-450. https://doi.org/10.1016/j.cja.2020.07.017

[15] Hung, J., Gonzalez, L. (2012). On parallel hybrid-electric propulsion system for unmanned aerial vehicles. Progress in Aerospace Sciences, 51: 1-17. https://doi.org/10.1016/j.paerosci.2011.12.001

[16] Cai, C., Wang, J., Nie, H., Zhang, P., Lin, Z., Zhou, Y. (2020). Effective-configuration WPT systems for drones charging area extension featuring Quasi-Uniform magnetic coupling. IEEE Transactions on Transportation Electrification, 6(3): 920-934. https://doi.org/10.1109/tte.2020.2995733

[17] Tyapkin, V., Korovin, A., Nerovny, V., Ishchuk, I., Kabulova, E. (2018). Characteristics of the Ground-Based User Equipment of Satellite radio navigation system employing pseudolites in noisy environments. International Review of Aerospace Engineering (IREASE), 11(2): 58. https://doi.org/10.15866/irease.v11i2.13938

[18] Borodin, A.A., Kabulova, E.G., Polozhentsev, K.A. (2016). Video detection of problems in the melting of consumable electrodes in a vacuum arc furnace. Steel in Translation, 46(5): 322-324. https://doi.org/10.3103/s0967091216050041

[19] Lei, T., Wang, Y., Jin, X., Min, Z., Zhang, X., Zhang, X. (2022). An optimal fuzzy Logic-Based energy management strategy for a fuel Cell/Battery hybrid power unmanned aerial vehicle. Aerospace, 9(2): 115. https://doi.org/10.3390/aerospace9020115

[20] Kousis, I., Manni, M., Pisello, A. (2022). Environmental mobile monitoring of urban microclimates: A review. Renewable and Sustainable Energy Reviews, 169: 112847. https://doi.org/10.1016/j.rser.2022.112847

[21] Adamashvili, N., Zhizhilashvili, N., Tricase, C. (2024). The integration of the internet of things, artificial intelligence, and blockchain technology for advancing the wine supply chain. Computers, 13(3): 72. https://doi.org/10.3390/computers13030072

[22] Bai, Y., Zhang, B., Xu, N., Zhou, J., Shi, J., Diao, Z. (2022). Vision-based navigation and guidance for agricultural autonomous vehicles and robots: A review. Computers and Electronics in Agriculture, 205: 107584. https://doi.org/10.1016/j.compag.2022.107584

[23] Alexandrov, I.A., Kuklin, V.Z., Muranov, A.N., Tatarkanov, A.A. (2022). Theoretical foundations of an algorithm of visualization of a set of points of a multidimensional space for use in anthropotechnical decision support systems. Proceedings of the Institute for System Programming of RAS, 34(4): 201-210. https://doi.org/10.15514/ispras-2022-34(4)-14

[24] Alexandrov, I.A., Kirichek, A.V., Kuklin, V.Z., Muranov, A.N., Chervyakov, L.M. (2023). Developing the concept of methodological support for designing and assessing the efficiency of information protection systems of standard information systems considering their vulnerabilities. Journal of Computer Science, 19(11): 1305-1317. https://doi.org/10.3844/jcssp.2023.1305.1317

[25] Petkovics, I., Simon, J., Petkovics, A., Covic, Z. (2017). Selection of unmanned aerial vehicle for precision agriculture with multi-criteria decision making algorithm. In IEEE 15th International Symposium on Intelligent Systems and Informatics (SISY), Subotica, Serbia, pp. 000151-000156. https://doi.org/10.1109/sisy.2017.8080543

[26] Gonzalez, D., Perez, J., Milanes, V., Nashashibi, F. (2015). A review of motion planning Techniques for Automated vehicles. IEEE Transactions on Intelligent Transportation Systems, 17(4): 1135-1145. https://doi.org/10.1109/tits.2015.2498841

[27] Bonadies, S., Gadsden, S.A. (2018). An overview of autonomous crop row navigation strategies for unmanned ground vehicles. Engineering in Agriculture Environment and Food, 12(1): 24-31. https://doi.org/10.1016/j.eaef.2018.09.001

[28] Wang, N.H., Yu, N.Y., Yuan, N.Q. (2011). Application of Dijkstra algorithm in robot path-planning. In 2011 Second International Conference on Mechanic Automation and Control Engineering, Hohhot, pp. 1067-1069. https://doi.org/10.1109/mace.2011.5987118

[29] Hameed, I.A. (2017). Coverage path planning software for autonomous robotic lawn mower using Dubins’ curve. In 2022 IEEE International Conference on Real-time Computing and Robotics (RCAR), Okinawa, Japan, pp. 517-522. https://doi.org/10.1109/rcar.2017.8311915

[30] Christiansen, M., Laursen, M., Jørgensen, R., Skovsen, S., Gislum, R. (2017). Designing and testing a UAV mapping system for agricultural field surveying. Sensors, 17(12): 2703. https://doi.org/10.3390/s17122703

[31] Cheein, F.A., Steiner, G., Paina, G.P., Carelli, R. (2011). Optimized EIF-SLAM algorithm for precision agriculture mapping based on stems detection. Computers and Electronics in Agriculture, 78(2): 195-207. https://doi.org/10.1016/j.compag.2011.07.007

[32] Lytridis, C., Kaburlasos, V.G., Pachidis, T., Manios, M., Vrochidou, E., Kalampokas, T., Chatzistamatis, S. (2021). An overview of cooperative robotics in agriculture. Agronomy, 11(9): 1818. https://doi.org/10.3390/agronomy11091818

[33] Vu, Q., Raković, M., Delic, V., Ronzhin, A. (2018). Trends in development of UAV-UGV cooperation approaches in precision agriculture. In Lecture Notes in Computer Science. Springer, Cham, pp. 213-221. https://doi.org/10.1007/978-3-319-99582-3_22

[34] Canese, L., Cardarilli, G.C., Di Nunzio, L., Fazzolari, R., Giardino, D., Re, M., Spanò, S. (2021). Multi-agent reinforcement learning: A review of challenges and applications. Applied Sciences, 11(11): 4948. https://doi.org/10.3390/app11114948

[35] Xiang, H., Tian, L. (2010). Method for automatic georeferencing aerial remote sensing (RS) images from an unmanned aerial vehicle (UAV) platform. Biosystems Engineering, 108(2): 104-113. https://doi.org/10.1016/j.biosystemseng.2010.11.003

[36] Doering, D., Benenmann, A., Lerm, R., De Freitas, E.P., Muller, I., Winter, J.M., Pereira, C.E. (2014). Design and Optimization of a Heterogeneous Platform for multiple UAV use in Precision Agriculture Applications. IFAC Proceedings Volumes, 47(3): 12272-12277. https://doi.org/10.3182/20140824-6-za-1003.02261

[37] Abir, M.B.S., Chowdhury, M.Z., Jang, Y.M. (2023). A software-defined UAV network using queueing model. IEEE Access, 11: 91423-91440. https://doi.org/10.1109/access.2023.3281421

[38] Mukherjee, A., Misra, S., Sukrutha, A., Raghuwanshi, N.S. (2019). Distributed aerial processing for IoT-based edge UAV swarms in smart farming. Computer Networks, 167: 107038. https://doi.org/10.1016/j.comnet.2019.107038

[39] Wei, Z., Zhu, M., Zhang, N., Wang, L., Zou, Y., Meng, Z., Wu, H., Feng, Z. (2022). UAV-assisted data collection for internet of things: A survey. IEEE Internet of Things Journal, 9(17): 15460-15483. https://doi.org/10.1109/jiot.2022.3176903

[40] Chodorek, A., Chodorek, R.R., Yastrebov, A. (2021). weather sensing in an urban environment with the use of a UAV and WebRTC-based platform: A pilot study. Sensors, 21(21): 7113. https://doi.org/10.3390/s21217113

[41] Jiao, S., Zhang, G., Zhou, M., Li, G. (2023). A Comprehensive review of research hotspots on battery management systems for UAVs. IEEE Access, 11: 84636-84650. https://doi.org/10.1109/access.2023.3301989

[42] Telli, K., Kraa, O., Himeur, Y., Ouamane, A., Boumehraz, M., Atalla, S., Mansoor, W. (2023). A comprehensive review of recent research trends on Unmanned Aerial Vehicles (UAVs). Systems, 11(8): 400. https://doi.org/10.3390/systems11080400

[43] Pramanik, P.K.D., Biswas, S., Pal, S., Marinković, D., Choudhury, P. (2021). A comparative analysis of multi-criteria decision-making methods for resource selection in mobile crowd computing. Symmetry, 13(9): 1713. https://doi.org/10.3390/sym13091713

[44] Tuyet Minh, D., Ba Dung, N. (2024). Hybrid algorithms in path planning for autonomous navigation of unmanned aerial vehicle: A comprehensive review. Measurement Science and Technology, 35(11): 112002. https://doi.org/10.1088/1361-6501/ad66f5

[45] Ming, R., Jiang, R., Luo, H., Lai, T., Guo, E., Zhou, Z. (2023). Comparative analysis of different UAV swarm control methods on unmanned farms. Agronomy, 13(10): 2499. https://doi.org/10.3390/agronomy13102499