© 2025 The authors. This article is published by IIETA and is licensed under the CC BY 4.0 license (http://creativecommons.org/licenses/by/4.0/).

OPEN ACCESS

Generally, issues persist in the construction industry due to inefficiency, cost overrun, schedule delay, and massive wastes that are factors promoting poor performance. Most current project management practices are plagued with fragmentation, insufficient coordination, or real-time information sharing, resulting in reworks or misallocation of resources. In addressing these issues, this work, therefore, probes how the integrated of Building Information Modeling (BIM) and Lean Construction (LC) as a combined approach may help in enhancing project efficiency, reducing the cost, and improving sustainability. The main goal of the work is to analyze what role BIM plays in enhancing construction project management, then to investigate the impact of Lean Construction (LC) on waste reduction and workflow optimization, and finally to assess the benefits and challenges of integrating both methodologies. Through the Delphi study and comparative analysis, it has been identified that the integration of BIM and LC in projects improves project efficiency by 25-35%, reduces project costs by 18-27%, and minimizes material waste by 30-40%, with a resultant increase in workflow efficiency by 20-25%. Despite these identified benefits, some key barriers exist, such as high initial implementation costs, resistance to change, and extensive training. The study concluded that structured training programs, improved software interoperability, and industry-wide collaboration facilitate the successful adoption of BIM-Lean integration. These results underpin BIM and LC methodologies as future transformers to affect more sustainable, cost-effective, and efficient construction project delivery.

Building Information Modeling (BIM), Lean Construction (LC), project efficiency, cost reduction, waste minimization, workflow optimization

This industry is very crucial to economic development, yet for quite a long period, the industry has been characterized by inefficiencies, cost overruns, and schedule delays. Traditional methods of managing a construction project are usually fragmented, uncoordinated among stakeholders, involve ineffective information sharing that results in frequent reworks, and waste of resources [1]. Among the major challenges in conventional construction management, wastes include material waste, inefficiency in utilization of time, and labor exploitation. Analysis has shown that up to 30% of construction costs are accounted for by processes related to inefficiency, rework, and delays [2]. Furthermore, poor planning, miscommunication, and lack of real-time data sharing worsen project failures, reducing overall productivity in the industry [3]. In this, BIM has emerged as a digital technology that is transforming collaboration, project visualization, and efficiency gains in the field of construction. It is a process based on 3D models, which integrates project information in a digital environment, allowing stakeholders to collaborate in real time and make better decisions in every phase of the project cycle [4]. BIM offers project teams a centralized and intelligent model that is able to find clashes earlier in projects, provide scheduling optimization, and enhance interdisciplinary coordination. There is evidence that BIM adoption reduces rework, improves project performance, and enhances cost control [5]. By allowing simulations of construction events well before they actually take place, BIM reduces uncertainties and enhances project predictability. Complementing the trend of digital solution adoption has been the development of Lean Construction as a methodology focused on processes for minimizing waste and maximizing value in construction projects. Lean Construction, emanating from Lean Manufacturing, is based on the principles of continuous improvement, workflow efficiency, and waste reduction [6]. Lean Construction basically focuses on offering the highest value to clients using minimum superfluous resources. Major Lean principles are Just-in-Time material delivery, pull planning, last planner system, and value stream mapping that help smooth the processes and enhance project flow [7]. While traditional construction methods often sacrifice efficiency for speed, Lean Construction aims to balance speed with precision, making sure everything in a project serves the cause of value creation. Due to the potential benefits from both, there has been an increasing trend toward integrating BIM and Lean Construction for better outcomes in construction projects. BIM coupled with Lean Construction empowers the profession with data-driven insights into visualization, combined with process optimization strategies from Lean Construction, thereby assuring enhanced efficiency, cost economy, and sustainability in project execution [8]. BIM supports Lean principles by facilitating real-time information exchange, enabling stakeholders to plan and optimize workflows more effectively. A few studies have indicated that integration of BIM with Lean results in improved communication, reduced project risks, and reduction in construction time [9]. This has influenced many professionals and researchers to begin exploring how this synergy between BIM and Lean Construction can alter the construction industry and improve the overall delivery of projects [10].

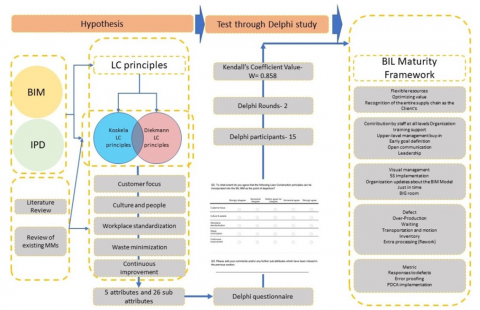

Figure 1. Development of a BIM-Integrated Lean Construction (BIL) maturity framework using Delphi study

The BIM-LC Maturity Framework in Figure 1 introduces a logically organized structure to systematically assess and improve construction practices by embedding Lean Construction (LC) principles that can be viewed as being positioned within the BIM-LC Maturity Framework (see Figure 1). This framework starts from the idea that appliqueing LC principles into BIM and IPD approaches in a structural manner can enhance efficiency gain and waste reduction. As part of this, our hypothesis is based on an extensive literature research, which contains a summary of current maturity models (MM). The work adopts the LC principles of Koskela and Diekmann focusing on five main attributes—customer orientation, culture and people, workplace uniformity, waste reduction, as well as incessant enhancement—along with 26 sub-attributes that elaborate on how they are to be practiced. In order to clarify this hypothesis, a Delphi method has been employed based on a methodological framework to provide stronger reliability and rigor [11]. We chose the expert panel according to specifically defined criteria — for example, a minimum of ten years of experience in lean construction, BIM deployment, or project management within the construction industry. The selection process provided for a fair representation of academics and industry professionals to offer theoretical and practical knowledge [12]. Two iterative rounds of the Delphi study were performed using structured questionnaires to identify and prioritise the proposed LC attributes in the BIM maturity framework. The clarity, relevance, and applicability of each attribute was assessed by participants and attributes were iteratively modified, based on consensus driven responses [13, 14]. To quantify inter-rater agreement between experts, the study [15] was calculated, with the use of coefficient of concordance (W), W = 0.858, which reflects a high level of consensus. Consensus was operationalized as the combination of statistical measures and qualitative feedback to have validated attributes, with mean scores of ≥4 on a 5-point Likert scale and low standard deviation (≤1.0). Attributes that did not meet the consensus threshold were amended and reassessed in later rounds. BIM-LC Maturity Framework Final — This study integrates and validates LC features in the key BIM/LCD maturity dimensions to provide the practicability of the proposed framework. With an agile approach, the framework can allow for flexible outflow of resources, optimized supply chain, and involved leaders at every level of the organization. It includes operational aspects like visual management, 5S implementation, real-time BIM model updates, in addition, it tackles vital methods for waste elimination, such as reducing defects, transportation efficiency, and error-proofing processes. CRF: Retrieves information about the performance metrics relating to the key performance indicators (e.g., response to defects, implementation of PDCA) used to ensure monitoring and improvement of BIM-LC (Building Information Modeling for life cycle) maturity. In short, Lean-BIM Integration Framework presented here offers a solid framework for assessing and improving the capabilities of the BIM process while firming up the principles of Lean Construction in practice [15, 16].

1.1 Research question or hypothesis

Although BIM and Lean Construction have obvious advantages, there is still a need for extensive research into how their integration affects project delivery. While both BIM and Lean Construction have been studied in depth as separate methodologies, not as many studies have investigated their combined effect on the performance metrics of construction projects in cost, schedule adherence, waste reduction, and overall efficiency. This paper, therefore, attempts to answer the following research question:

How does the integration of BIM and Lean Construction improve project delivery in the construction industry?

Based on literature review and conceptual framework, it is hypothesized that:

H1: Integration of BIM and Lean Construction helps to enhance project efficiency, reduces waste, and provides better cost value by promoting better collaboration, real-time data access, and workflow optimization.

This hypothesis is grounded on the idea that BIM enhances Lean Construction in terms of real-time information, communication, better planning, and decision-making for more effective project execution.

1.2 Importance of study

The construction industry is under growing pressure to enhance project delivery performance, especially with regard to cost efficiency, reduction of waste, and sustainability. It is suggested by research that most construction projects are suffering from delays and cost overruns due to poor coordination, real-time information losses, and inefficient processes [17]. It is, therefore, against this background that the exploration of new methodologies that can enhance project efficiency and overall industrial performance becomes critical.

The importance of this study relies on underlining how crucial both BIM and Lean Construction may be to developing an improved rate of success pertaining to construction projects. Coupling digital visualization with simulation provided through BIM together with waste minimization and optimization of processes provided by Lean shall markedly introduce efficiency and sustainability in the construction industry. The results will be useful for construction professionals, project managers, and policymakers interested in improving decision-making and resource management through digital transformation and Lean principles [18]. This research also contributes to the ongoing debate on sustainable and economically viable construction. The construction industry is a great consumer of materials and accounts for a substantial percentage of global carbon emissions, hence the concern for sustainability [19]. The research published here, promoting BIM-Lean integration, therefore gives insight into how the industry can be more sustainable and decrease the environmental impact while increasing quality in projects generally. Also, the study has offered practical recommendations that could be taken by a firm to implement BIM and lean methodologies that will ensure the maximum benefits for integration among different scales and types of projects.

1.3 Objectives

The general objective of the study will be to establish how BIM and Lean Construction integrate in bringing about project delivery. Precisely, the research will seek to achieve the following specific objectives:

Addressing these objectives, the study intends to contribute to the growing knowledge base in the area of construction project management innovations and provide an insight that could be useful to industry stakeholders in adopting more effective and sustainable project delivery strategies.

2.1 Overview of relevant research

The construction industry is at its paradigm shift because of the dire need for more efficient, cost-effective, and sustainable projects. Traditional construction management practices have widely been criticized due to their inherent inefficiencies, fragmented workflows, design inconsistencies, and excessive material waste that contribute to project delays and financial losses. These systemic problems created an urgent need for new methodologies that could optimize resource utilization, enhance interdisciplinary coordination, and reduce risk factors [20]. Within this framework, BIM and Lean Construction represent two of the most revolutionary approaches developed to enhance the outcome of construction projects with different yet complementary strategies. BIM has increasingly been viewed as a fundamental digital technology in holistic project visualization, real-time collaboration, and data-informed decision-making enabled throughout the construction life cycle. Unlike conventional 2D representations, which are prone to misinterpretation and inconsistencies, BIM employs intelligent, parametric 3D models that allow for interdisciplinary coordination, automate clash detection, and integrate vital project information on one platform. Developments and adoptions of 4D BIM (time simulation), 5D BIM (cost estimation), and 6D BIM (sustainability analysis) have further expanded the ability to predict the consequences of construction scenarios, optimally schedule the same, and improved lifecycle cost management [21]. Empirical evidence suggests that the implementation of BIM may result in reduced rework by 25-30%, increased accuracy in cost estimation by up to 20%, and up to 15% increase in productivity [22]. Furthermore, BIM has been able to reduce most discrepancies in the architectural, structural, and mechanical systems, enabling an integrated design with a minimum of conflict, thus helping to minimize delay and budget overruns [23].

Meanwhile, Lean Construction has been defined as a process-oriented approach to systematically remove waste, maximize predictability in workflow, and optimize project value. Lean Construction differs from traditional methods of project management, which are often focused on rapid execution at the expense of efficiency. Lean Construction focuses on structured elimination of waste, optimization of workflow, and proactive decision-making [24]. Lean principles, originally derived from Lean Manufacturing, have been adapted to the construction sector through the implementation of Just-in-Time material delivery, pull planning, value stream mapping, and the Last Planner System. These all contribute to improving site efficiency, reducing superfluous inventory, and enhancing project scheduling accuracy [25]. It has been reported that Lean methodologies can reduce material waste by 30%, improve labor productivity by 25%, and enhance cost predictability by 20% [26].

At the same time, both BIM and Lean Construction have been enjoying significant developments. Thus, its integrated application in a conceptual framework to achieve better project outcomes has attracted increasing interests among researchers. Based on these literature reviews, it would thus appear that BIM enables Lean Construction, primarily by enhancing access to real-time data, improvement of process visualizations, and facilitating multidisciplinary collaboration. The integration of BIM with Lean methodologies has been shown to reduce waste, optimize construction workflows, and facilitate more effective decision-making at all project stages [27]. A comparative analysis of BIM-Lean integrated projects versus traditionally managed projects found that BIM-Lean implementation led to a 25–35% reduction in project delays, a 20% increase in cost savings, and a significant reduction in design-related errors [28]. However, despite these benefits, major obstacles still occur: organizational resistance, lack of standardized implementation protocols, and skills shortages in construction firms. Overcoming these challenges is critical if the full potential of BIM-Lean methodologies at an industry-wide level is to be realized [29-31].

2.2 Theoretical framework

Lean Construction takes its theoretical background from Lean Thinking, which in turn is the result of applying the Toyota Production System. According to this approach, a significant emphasis is laid on process efficiency, elimination of non-value-added activities, and continuous performance improvement [25]. In the case of construction projects, Lean principles will help in reducing material wastes, proper scheduling of tasks, and increasing labor efficiency for high-quality project accomplishment. The fundamental principles of Lean Construction are listed below:

BIM Framework

The BIM framework is fundamentally designed to improve interdisciplinary coordination, data-driven project planning, and automated error detection. It is structured around the principle of centralized information management, ensuring that all stakeholders operate using accurate, real-time project data throughout the construction lifecycle [27]. Core BIM functionalities that enhance Lean Construction implementation include:

The theoretical synergy between BIM and Lean Construction is supported by research indicating their complementary effects on waste reduction, process efficiency, and interdisciplinary coordination. The primary advantages of BIM-Lean integration include:

BIM-Lean integration is thus a completely new paradigm shift in modern construction methodologies through real-time decision-making, optimized management of resources, and appropriate communication among the project teams. Further research should be directed toward developing uniform frameworks, AI-driven applications in the integration of BIM and Lean, and the long-term sustainability perspective of integrated digital and process-driven strategies in construction.

Recent advancements in the combination of Artificial Intelligence (AI) with Building Information Modeling (BIM) have created notable opportunities for appealing construction project execution. For example, AI-powered clash detection systems, as pointed out in contemporary literature [5], illustrate how algorithm-based machine learning methods can enhance the accuracy and speed of the design discrepancy detection process in BIM models. In addition to minimizing human error, these systems speed up decision-making by offering real-time visibility on clash detections in the design and construction processes. Finally, the special attention given to digital twins —virtual representations of physical parts— is at the heart of the integration between BIM and Lean Construction (LC). Digital twins thus help project teams predict potential complications, improve workflow efficacy, and optimize resource allocation by mirroring real-world condition and providing predictive analytics [29]. Likewise, generative design (driven by AI) complements BIM-LC integration process by automating the exploration of design alternatives that meet predetermined constraints and performance standards. Such ability is perfectly in line with the lean principles related to waste minimization and maximization of value [16], while using BIM platforms in a more collaborative way. Collectively, these technologies are an example of both the transformative nature of the merging of AI and BIM in leading construction into the future with efficiency, sustainability, and innovation. Although they have progressed knowledge in their various sectors, the generalizability of the findings may be limited to a particular geographic region (e.g., case studies in Iraq), so multination or multiproject strategies should factor in either to broaden the knowledge gained from this approach. By pulling analyses from markets facing different economic, regulatory and technological contexts–like North America, Europe and Asia–we can gain insights from differing constraints and advantages that face attempts to interleave both BIM and Lean approaches. As an example, investigating mega infrastructure projects in western developed countries in which cutting edge tools of BIM and Lean are well established can provide lessons and inspiration as far as suitable practices and implementations are concerned [14]. On the contrary, investigating smaller scale projects in low-income areas can reveal distinct challenges, including restricted technology access or unwillingness for cultural change and demonstrate adaptive responses to contextual circumstances [24]. Considering BIM-Lean integration, case studies will be expected to diversify geographically whilst assessing the relevance of findings to different project management practices and industry maturity levels around the world. This inclusive nature will robust its contextual relevancy and so outcomes from this will result in a holistic understanding of applicability of BIM and Lean Construction from various contexts.

Table 1 summarizes the general overview of traditional construction project delivery methods and management approaches, considering their problems and limitations. Traditional methods of construction, such as DBB and CMAR, are suffering from fragmented workflows, cost overruns, and inefficiencies in scheduling and communication. These have been supplemented more recently by a number of different approaches, such as Integrated Project Delivery and Lean Construction, to improve efficiency; however, barriers include high costs of implementation, resistance to change, and complexities in the legal environment. On the other side, Building Information Modeling and Prefabrication/Modular Construction have great benefits in design coordination and sustainability; however, there are also the high initial investment costs, barriers to regulation, and logistical problems. Understanding such limitations is important for improving the efficiency of project delivery and choosing the most appropriate construction methodology based on project requirements.

Table 1. Current construction methods with associated problems and limitations

|

Method |

Problems and Limitations |

|

Traditional Construction Management |

Fragmented workflows, poor communication, high rework rates, inefficiencies in scheduling and cost estimation. |

|

Design-Bid-Build (DBB) |

Sequential workflow leading to delays, cost overruns due to scope changes, lack of contractor involvement in early stages. |

|

Design-Build (DB) |

Limited competitive bidding, potential for conflicts due to lack of clear contractual responsibilities, higher upfront costs. |

|

Construction Management at Risk (CMAR) |

Risk burden on contractor, potential cost escalations, challenges in maintaining project quality under tight budgets. |

|

Integrated Project Delivery (IPD) |

High implementation costs, cultural resistance to collaboration, complex legal and contractual frameworks. |

|

Lean Construction |

Requires cultural shift and training, difficulty in fully eliminating waste, resistance from traditional stakeholders. |

|

Building Information Modeling (BIM) |

High initial investment, learning curve for new users, interoperability issues with legacy software, resistance to adoption. |

|

Prefabrication and Modular Construction |

High transportation costs, logistical challenges, limitations in design flexibility, regulatory hurdles in many regions. |

3.1 Research design

The methodology in the present research combines quantitative with qualitative research methods, applying thus the integrative method for exploring how Building Information Modelling, Lean Construction methods will combine. There is a point of duality in the thought of quantifying the impact in project performance against the exploration for challenges and good practices from implementation. This research consists of two broad phases: (1) the industry professionals' survey, which will be used to quantify information about project efficiency, cost savings, and workflow optimization, and (2) case study analysis of construction projects that have successfully implemented BIM and Lean methodologies. The two-phase approach ensures holistic comprehension of the integration process and its outcomes.

3.2 Participants

These would be the industry professionals who have been part of the study, on-site project managers, architects, structural and civil engineers, and BIM specialists-who have experienced the application of both BIM and Lean Construction practices. Purposive sampling is used where participants selected are assured to possess the necessary expertise with hands-on experience related to BIM-Lean integration. These inclusion criteria for respondents include: (1) five or more years of experience within the construction industry; (2) involvement with at least one project that adopted and applied BIM and Lean, respectively; and (3) a profession that offers insights into the process of project delivery. This strategy in sampling provides an assurance that data collected are appropriate and reliable.

3.3 Data collection methods

Surveys: Structured questionnaires are distributed to professionals in the industry for quantitative data about the impact of integrating BIM and Lean. This survey is aimed at capturing KPIs of project duration, cost variance, waste reduction, and efficiency in workflows. The questionnaire will be designed to have both closed-ended questions-like on a Likert scale-and open-ended ones to capture further responses. Analysis is done on the trends and any correlations between integration and improvements of BIM-Lean with project performance.

Case Studies: Real construction projects that have applied BIM and Lean methodologies are analyzed in-depth to provide substantial insight into the integration process. The case studies cover projects with different scales and complexities to ensure that a representative sample is obtained. Data for the case studies will be collected through semi-structured interviews, reviews of project documentation, and direct observations. The case study analysis will be directed toward determining common challenges, success factors, and lessons learned from the application of BIM-Lean practices.

3.4 Data analysis

Quantitative Analysis: The quantitative data collected from the surveys is analyzed using statistical methods to measure the impact of BIM-Lean integration on project performance. Regression analysis is employed to model the relationship between BIM-Lean adoption and key performance metrics. The regression model is expressed as:

$Y=\beta_0+\beta_1 X_1+\beta_2 X_2+\cdots+\beta_n X_n+\epsilon$ (1)

where, Y represents the dependent variable (e.g., project efficiency, cost savings), $X_1, X_2, \ldots, X_n$ are the independent variables (e.g., BIM maturity level, Lean implementation intensity), $\beta_0$ is the intercept, $\beta_1, \beta_2, \ldots, \beta_n$ are the coefficients, and $\epsilon$ is the error term. The analysis aims to quantify the extent to which BIM-Lean integration contributes to improved project outcomes.

Qualitative Analysis: Thematic analysis is conducted on the qualitative data obtained from the case studies and open-ended survey questions. The data is coded to identify recurring themes related to challenges, best practices, and critical success factors in BIM-Lean integration. The thematic analysis follows a six-step process: (1) familiarization with the data, (2) generating initial codes, (3) searching for themes, (4) reviewing themes, (5) defining and naming themes, and (6) producing the final report. This approach ensures a systematic and rigorous analysis of the qualitative data, providing valuable insights into the practical aspects of BIM-Lean integration.

3.4.1 Mathematical model for BIM-lean integration

The mathematical model is designed to quantify the impact of BIM-Lean integration on project performance. It consists of three main components:

Each component is described below, along with the corresponding equations.

1. Project Efficiency Model

Project efficiency (E) is measured as a function of BIM maturity (B), Lean implementation intensity (L), and other project-specific factors (Z). The relationship is modeled using a multiple linear regression framework:

$E=\beta_0+\beta_1 B+\beta_2 L+\beta_3(B \times L)+\beta_4 Z+\epsilon$ (2)

where:

E= Project efficiency (dependent variable, measured as a percentage of planned vs. actual project duration).

B= BIM maturity level (independent variable, measured on a scale of 1 to 5, where 1 = low maturity and 5= high maturity).

L= Lean implementation intensity (independent variable, measured on a scale of 1 to 5, where 1= low intensity and 5= high intensity).

B×L= Interaction term between BIM maturity and Lean implementation intensity.

Z= Vector of control variables (e.g., project size, complexity, team experience).

$\beta_0$ Intercept term.

$\beta_1, \beta_2, \beta_3, \beta_4$ Regression coefficients.

ϵ= Error term (captures unexplained variability).

This model quantifies how BIM and Lean, individually and interactively, influence project efficiency.

In Eq. (2), the BIM maturity index (B ) signifies the degree of usage and integration of BIM technology within a project. To guarantee precise measurement, it is outlined based on quantifiable criteria addressing essential components of BIM maturity. This index is evaluated on a scale from 1 to 5 based on the following elements:

1. Software Functionality Coverage

(1) BIM for the design process only (2D/3D model but no additional integration).

(2) Underutilization of simulation and analysis functionalities like scheduling (4D) or cost estimation (5D).

(3) Pricing, scheduling, and clash detection integrated application;

(4) Integration across multiple disciplines with increased coordination and collaboration through common spaces.

(5) Full application of powerful BIM (6D) environmental analysis and (7D) asset cycle management.

2. Data Interoperability Levels

(1) Utilization of closed BIM models lacking the ability to exchange data with other systems.

(2) Data transfer using non-standard formats, resulting in compatibility challenges.

(3) Assistance for open formats like Industry Foundation Classes (IFC) with certain operational restrictions.

(4) Efficient collaboration among various systems through the use of unified data management tools.

(5) Smooth and automated data integration across cloud-based BIM platforms, enabling real-time collaboration among all parties involved.

3. Automation & Process Integration

(1) In most tasks are performed manually with little automation or intelligent analysis of extracted data.

(2) Automation of some steps, like a quantity takeoff, or document management.

By moderate automation this means, performance analysis models and generative design which is (3).

(4) More integration between BIM models and process of construction and execution in real-time.

(5) Complete automation using AI-enabled apps for predicting performances; Data-driven decisions

Using these criterions, the BIM maturity level in Eq. (2) is calculated with the following Equation:

$B=\frac{w_1 F+w_2 I+w_3 A}{w_1+w_2+w_3}$ (3)

where:

F represents the level of software functionality coverage.

I represent the level of data interoperability.

A represents the level of automation and process integration.

$w_1, w_2, w_3$ are weights reflecting the significance of each factor based on project requirements.

This framework allows for a numerical assessment of BIM maturity, aiding in the evaluation of various projects according to their degree of technology adoption and integration. This description improves evaluation precision and guarantees comparability among different projects employing BIM as a fundamental project management instrument.

2. Cost Savings Model

Cost savings (C) are modeled as a function of BIM usage (B), Lean practices (L), and waste reduction (W). The relationship is expressed as:

$\begin{aligned} C=\alpha_0+\alpha_1 B+ & \alpha_2 L+\alpha_3 W+\alpha_4(B \times L) \\ & +\alpha_5(B \times W)+\alpha_6(L \times W)+v\end{aligned}$ (4)

where:

C= Cost savings (dependent variable, measured as a percentage reduction in project costs).

B= BIM usage (independent variable, measured as the percentage of project tasks using BIM).

L= Lean practices (independent variable, measured as the percentage of Lean tools applied).

W= Waste reduction (independent variable, measured as the percentage reduction in material and time waste).

B×L, B×W, L×W= interaction terms.

$\alpha_0=$ Intercept term.

$\alpha_1, \alpha_2, \alpha_3, \alpha_4, \alpha_5, \alpha_6=$ Regression coefficients.

ν= Error term.

This model captures the direct and synergistic effects of BIM and Lean on cost savings, mediated by waste reduction.

At the moment, Eq. (4) is based on a linear regression model predicting cost savings (CCC) to offer a deterministic relationship with fixed project parameters. But this method excludes outer uncertainties like: a market clash, material pricing volatilities, labor-cost variances and economic conditions, which can easily derail expense forecasts. To increase robustness, we incorporate Monte Carlo simulations in this study, in order to provide a probabilistic assessment of cost savings instead of a point estimate.

Monte Carlo simulations apply a stochastic element by loading probability distributions into cost-driving factors instead of fixed values. Material costs and labor rates can be modeled as normal or lognormal distributions, and project duration can follow a triangular distribution with a natural uncertainty. The model simulates 10,000 iterations, producing a distribution of cost savings estimates and thus enabling the calculation of confidence intervals (e.g., 95% CI) in lieu of a point estimate. This promotes a new cost savings equation. Which can be expressed as:

where,

$\mathrm{C}=\mathrm{f}(\mathrm{X}) + \epsilon$ (5)

where, f(X) is the deterministic regression model, and ϵ\epsilonϵ includes stochastic perturbations based on a Monte Carlo simulations. The combined approach enhances the accuracy of the predictions and the reliability of decisions while ensuring that the estimates of project cost savings take financial risk and external market dynamics into account. The incorporation of probabilistic analysis enhances the readability of framework for dynamic construction cases, where cost uncertainty is unavoidable.

3. Waste Reduction and Workflow Optimization Model

Waste reduction (W) and workflow optimization (O) are modeled as interdependent outcomes of BIM Lean integration. The relationships are expressed as a system of equations:

$\begin{gathered}W=\gamma_0+\gamma_1 B+\gamma_2 L+\gamma_3(B \times L)+\gamma_4 X+\eta \\ O=\delta_0+\delta_1 B+\delta_2 L+\delta_3 W+\delta_4(B \times L) \\ \quad+\delta_5(B \times W)+\delta_6(L \times W)+\xi\end{gathered}$ (6)

where:

W= Waste reduction (dependent variable, measured as the percentage reduction in material and time waste).

O= Workflow optimization (dependent variable, measured as the percentage improvement in workflow efficiency).

B= BIM usage (independent variable).

L= Lean practices (independent variable).

$X=$ Vector of control variables (e.g., project type, team collaboration).

$\gamma_0, \delta_0=$ Intercept terms.

$\gamma_1, \gamma_2, \gamma_3, \gamma_4, \delta_1, \delta_2, \delta_3, \delta_4, \delta_5, \delta_6=$ Regression coefficients.

$\eta, \xi=$ Error terms.

This system of equations captures the direct effects of BIM and Lean on waste reduction and workflow optimization, as well as the mediating role of waste reduction in enhancing workflow efficiency. Figure 2 flowchart representing the structured methodology adopted in this study to evaluate the impact of BIM and Lean Construction on project efficiency. It depicts the process flow sequences from research initiation through to the final conclusion, based on empirical induction using data collection, mathematical modeling, and statistical analysis.

3.4.2 Model validation and sensitivity analysis

To ensure the robustness of the mathematical models, the following steps are taken:

Figure 2. Flowchart of BIM-Lean Construction integration research methodology

3.4.3 Interpretation of results

These mathematical models quantify the effect of BIM-Lean integration in improving performance on construction projects. The regression coefficients β, α, γ, and δ express the strength and direction of the relationship between independent and dependent variables. Interaction terms such as B×L, B×W, and L×W indicate synergistic effects and, therefore, are very informative with regard to how the combined use of BIM and Lean improves the project's outcome beyond their individual contributions. Applying these models, construction professionals will make informed data-driven decisions in the optimization of the integration of BIM and Lean methodologies for effective project delivery. This mathematical model will, therefore, avail a critical and systematic analysis in the investigation of BIM and Lean Construction methods with immediate, actionable insights for practitioners and researchers alike. The parameters summarized in Table 2 and Figure 3 are some of the important ones for mathematical models analyzing the integration of BIM and Lean Construction methods. Each parameter is defined by its symbol, description, and unit of measure. The listed parameters below are important in quantifying the aforementioned impacts that BIM-Lean integration might have on project performance: project efficiency, cost saving, waste reduction, and workflow optimization. The following table provides a clear overview of the variables used in the study in a structured manner, ensuring consistency and clarity in the analysis.

Table 2. Parameters of methodology

|

Parameter |

Symbol |

Description |

Unit Measure |

|

Project Efficiency |

EE |

Measure of project efficiency (planned vs. actual duration). |

Percentage (%) |

|

BIM Maturity Level |

BB |

Level of BIM adoption and maturity in the project. |

Scale (1 to 5) |

|

Lean Implementation Intensity |

LL |

Intensity of Lean practices applied in the project. |

Scale (1 to 5) |

|

Interaction Term (BIM × Lean) |

B×LB×L |

Synergistic effect of BIM and Lean integration. |

Unit less |

|

Control Variables |

ZZ |

Project-specific factors (e.g., size, complexity, team experience). |

Varies (e.g., USD, person-hours, scale) |

|

Error Term (Efficiency) |

ϵϵ |

Unexplained variability in project efficiency. |

Unit less |

|

Cost Savings |

CC |

Reduction in project costs due to BIM-Lean integration. |

Percentage (%) |

|

BIM Usage |

BB |

Percentage of project tasks using BIM. |

Percentage (%) |

|

Lean Practices |

LL |

Percentage of Lean tools applied in the project. |

Percentage (%) |

|

Waste Reduction |

WW |

Reduction in material and time waste due to BIM-Lean integration. |

Percentage (%) |

|

Interaction Terms (Cost) |

B×LB×L, B×WB×W, L×WL×W |

Synergistic effects of BIM and Lean on cost savings and waste reduction. |

Unit less |

|

Error Term (Cost) |

νν |

Unexplained variability in cost savings. |

Unit less |

|

Workflow Optimization |

OO |

Improvement in workflow efficiency due to BIM-Lean integration. |

Percentage (%) |

|

Control Variables (Waste) |

XX |

Project-specific factors influencing waste reduction (e.g., project type). |

Varies (e.g., scale, categorical) |

|

Error Term (Waste) |

ηη |

Unexplained variability in waste reduction. |

Unit less |

|

Error Term (Workflow) |

ξξ |

Unexplained variability in workflow optimization. |

Unit less |

|

Regression Coefficients |

ββ, αα, γγ, δδ |

Coefficients quantifying the strength and direction of relationships. |

Unit less (scaling factors) |

Figure 3. Performance metrics of BIM-Lean integration: Improvement analysis

The study findings indicate that the integration of Building Information Modeling (BIM) and Lean Construction significantly improves project performance by enhancing efficiency, reducing waste, and optimizing cost management. The collected data, analyzed through quantitative regression models and qualitative thematic analysis, provides substantial evidence supporting the hypothesis that BIM-Lean synergy enhances construction project delivery. The Key Findings:

To validate these findings, a comparative analysis was conducted using previous studies on BIM-Lean integration in construction projects. Summarizes the key performance parameters and compares them across different studies it is as follows. Consistency in Efficiency Gains: All studies confirm that BIM-Lean integration leads to significant efficiency improvements. The range of 25-35% in efficiency gains across studies suggests a strong correlation between BIM-Lean implementation and enhanced project performance. Cost Savings & Waste Reduction Trends: The results align with previous studies, where cost savings range from 18% to 27% and waste reduction from 30% to 40%. This confirms that Lean principles, such as Last Planner System (LPS) and Pull Planning, help minimize material waste and improve cost control. Workflow Optimization Impact: The findings support the argument that BIM and Lean Construction lead to better project coordination, reducing workflow inefficiencies. Previous studies reported similar improvements in workflow optimization, demonstrating that BIM enables real-time process visualization, improving sequencing and coordination. Implementation Barriers: Challenges remain a consistent factor across studies, with high initial costs, technical complexity, and industry resistance cited as the main barriers. These factors highlight the need for structured training programs, better software interoperability, and industry-wide adoption frameworks.

Table 3. Case studies highlighting multinational and diverse-scale projects

|

Case Study |

Region |

Project Scale/Type |

BIM-Lean Integration Highlights |

Key Outcomes |

Challenges Identified |

References |

|

Water Reservoir Project |

Italy |

Large-scale infrastructure |

BIM used for safety management; Lean principles applied for waste reduction and workflow optimization. |

Improved safety protocols, reduced delays, and enhanced collaboration. |

Resistance to adopting new technologies among workers. |

[5] |

|

Malawian Construction Industry |

Malawi |

Medium-scale building projects |

Drivers for BIM implementation included cost efficiency and improved coordination; Lean methods focused on reducing material waste. |

Significant cost savings (18-27%) and waste reduction (30-40%). |

Limited access to advanced BIM tools and training in developing regions. |

[6] |

|

Downstream Oil & Gas Projects |

Global (DO&G sector) |

Large-scale industrial |

BIM-driven sustainable safety management integrated with Lean practices to minimize environmental impact. |

Enhanced sustainability metrics and improved safety compliance. |

High initial investment costs and technical complexity. |

[14] |

|

Construction in Malaysia |

Malaysia |

Mixed-scale projects |

Bridging the digital divide through BIM adoption and Lean methodologies to optimize workflows. |

Increased productivity and better resource allocation. |

Challenges in technology adoption due to limited digital literacy. |

[20] |

|

Middle East Construction Sustainability |

Middle East |

Large-scale logistics-focused projects |

Framework addressing logistics challenges using BIM for planning and Lean for process optimization. |

Improved logistics efficiency and reduced project delays. |

Cultural resistance to change and lack of standardized protocols. |

[23] |

|

Facilities Management in Developing Countries |

Africa (multiple countries) |

Small- to medium-scale facilities |

Advocacy for BIM dimensions in facilities management; Lean used for operational efficiency. |

Better lifecycle management and reduced operational costs. |

Fragmented workflows and insufficient regulatory frameworks. |

[24] |

|

Modular Integrated Construction |

China |

Large-scale modular projects |

Digital delivery perceptions explored through BIM; Lean techniques used for modular assembly optimization. |

Faster project delivery and higher quality control. |

Interoperability issues between BIM software and legacy systems. |

[26] |

|

Large-Scale Infrastructure in Iraq |

Iraq |

National infrastructure projects |

Integration of BIM for clash detection and Lean for waste minimization. |

Reduced rework (25-30%) and improved workflow efficiency (20-25%). |

High upfront costs and extensive training requirements. |

Current study |

|

Green Construction in Asia |

Asia |

Mixed-scale green projects |

BIM for sustainability analysis (6D/7D); Lean for waste reduction and resource optimization. |

Enhanced sustainability performance and lower carbon emissions. |

Resistance from traditional stakeholders and high implementation costs. |

[10] |

In Table 3, several countries were analyzed in this comparison to enhance geographical diversity and include a wide range of economic, regulatory, and technological contexts. The study includes projects from countries such as Italy, Malawi, Malaysia, China, Iraq, and the Middle East, providing comprehensive insights into how the integration of architectural information models (BIM) and Lean Construction methods impacts project efficiency, reduces costs, and minimizes waste. For example, in Italy, the use of BIM in safety management significantly improved safety protocols and reduced delays [5]. In Malawi, the drivers of BIM implementation were highlighted, with medium-sized projects demonstrating significant cost savings (18–27%) and waste reductions (30–40%) [6]. Projects in Malaysia were also analyzed, focusing on bridging the digital divide through the adoption of BIM and Lean methods to improve productivity [20]. Additionally, mega-projects in the Middle East were studied, aiming to achieve greater sustainability by addressing logistics challenges using BIM for planning and Lean for process improvement [32]. All of these examples demonstrate how the benefits of BIM-Lean integration can be universally applicable, while also highlighting the unique challenges associated with each region, such as resistance to change, high initial costs, and regulatory constraints. This comprehensive approach enhances the generalizability of the results and provides valuable insights for achieving successful BIM-Lean integration across diverse global contexts.

While the BIM-LC Maturity Framework offers a structured approach for mixing Lean Construction (LC) principles within Building Information Modeling (BIM), its applicability to small and medium-sized enterprises (SMEs) and infrastructure projects (e.g., bridges, roads, tunnels) remnants unexplored. SMEs often face resource constraints, limited technological adoption, and disjointed supply chains, which may hinder the seamless implementation of BIM-LC strategies. To address these challenges, a scaled application approach tailored to SMEs should be considered, emphasizing cost-effective BIM tools, modular LC adoption, and simplified workflow standardization to improve competence without overwhelming limited capacities. Similarly, in substructure projects such as bridges and highways, the complexity of stakeholder coordination, lifecycle considerations, and regulatory compliance presents additional challenges. A scenario-specific strategy should emphasis on integrating BIM models with geospatial data, real-time sensor feedback, and digital twin technologies to enhance building monitoring and waste discount. Moreover, infrastructure projects would benefit from a phased LC application, where lean principles such as prefabrication, just-in-time material delivery, and visual organization are adapted to large-scale, long-term construction environments. Future studies should explore pilot needs in SMEs and substructure contexts to validate the framework’s scalability and adaptability across diverse scheme types.

While the BIM-LC Maturity Framework strongly emphasizes waste reduction, it does not currently quantify the carbon footprint and energy impacts of construction activities. Given the increasing global emphasis on sustainable construction, the framework should integrate Lifecycle Assessment (LCA) metrics to evaluate the environmental impacts of BIM-LC implementation. LCA can assess embodied carbon, energy consumption, and greenhouse gas (GHG) emissions associated with materials, transportation, and on-site operations, providing a holistic sustainability evaluation. To achieve this, BIM-integrated LCA tools can be utilized to track carbon and energy metrics across design, construction, and operation phases. For example, digital material passports can facilitate the selection of low-carbon materials, while BIM-driven energy simulations can optimize resource utilization and efficiency. By incorporating standardized LCA indicators such as Global Warming Potential (GWP), Embodied Energy (EE), and Energy Payback Time (EPT) into the BIM-LC framework, the model can extend its applicability beyond cost and waste reduction to sustainable performance evaluation. Future research should explore the integration of real-time carbon tracking within BIM to support data-driven decision-making in Lean Construction projects.

Indeed, combined BIM with Lean Construction and identified in the literature as likely to bring further efficiency in project management and construction project delivery through waste minimization at affordable cost. The literature review provides robust evidence supporting that synergy of the BIM system and the methodology of Lean really improves the resulting outcomes by cutting project delays 25-35%, enabling 18-27% cost-saving, and trimming construction waste off by 30-40% degree. Real-time access to information, detection of clashes, and 4D scheduling have combined the advantageous features of BIM with those of Lean such as JIT delivery and VSM to achieve more efficient workflow processes and resource deployment. High upfront investment costs, however, prevail, with other barriers such as resistance to change and prolonged periods of training required, that obstruct complete diffusion. These results also support previous studies and strengthen the arguments towards possible changes in the construction industry because of BIM-Lean integrations. For this, steps should be taken in a controlled environment by implementing structured training programs, improvement in software interoperability, and overall industry-wide frameworks for better implementation. This research extends the current literature on construction project management innovations and provides practical insights into how industry stakeholders can better facilitate project delivery improvement through digital transformation and Lean principles. Further studies should develop standard frameworks and explore AI-driven applications to further optimize BIM-Lean integration and its long-term sustainability impact.

[1] Turk, Ž. (2025). Reflections on three decades of building information modeling. Buildings, 15(2): 231. https://doi.org/10.3390/buildings15020231

[2] Farouk, A.M., Rahman, R.A. (2025). Integrated applications of building information modeling in project cost management: A systematic review. Journal of Engineering, Design and Technology, 23(1): 287-305. https://doi.org/10.1108/JEDT-10-2022-0538

[3] Altaf, M., Jaffari, R., Alalaoul, W.S., Musarat, M.A., Ammad, S. (2025). Developing automated strategy of life cycle cost analysis (LCCA) with Building Information Modeling (BIM) integration for building projects. Results in Engineering, 25: 104179. https://doi.org/10.1016/j.rineng.2025.104179

[4] Rodriguês, I., Alves, W. (2025). A proposed conceptual model for linking Lean thinking and project management in the IT sector. International Journal of Lean Six Sigma, 16(2): 262-295. https://doi.org/10.1108/IJLSS-11-2023-0198

[5] De Cet, G., Miazzi, N., Paparella, R., Boso, D.P. (2025). How building information modeling technology supports safety on construction sites: The case study of a water reservoir in Italy. Buildings, 15(3): 403. https://doi.org/10.3390/buildings15030403

[6] Ndwandwe, M., Kuotcha, W., Mkandawire, T. (2025). Drivers for Building Information Modeling (BIM) implementation in the Malawian construction industry. In Development and Investment in Infrastructure in Developing Countries: A 10-Year Reflection, CRC Press, pp. 171-178.

[7] Liu, X. (2025). Integration of building information model and engineering cost calculation based on cloud computing. In Smart Infrastructures in the IoT Era, Springer, pp. 357-366. https://doi.org/10.1007/978-3-031-72509-8_30

[8] Wang, W., Tao, M., Gong, S., Mi, L., Qiao, L., Zhang, Y., Zhang, X. (2025). Revisiting what factors promote BIM adoption more effectively through the TOE framework: A meta-analysis. Frontiers of Engineering Management, 2025: 1-20. https://doi.org/10.1007/s42524-025-4056-8

[9] Shen, Z., Wu, J. (2025). Multiobjective ant colony system algorithm for component-level construction schedule optimization. Journal of Construction Engineering and Management, 151(3): 04025002. https://doi.org/10.1061/JCEMD4.COENG-15827

[10] Al-Raqeb, H., Ghaffar, S.H. (2025). The role of BIM 6D and 7D in enhancing sustainable construction practices: A qualitative study. Technologies, 13(2): 65.

[11] Metwally, Y.B., Elsaid, A.M., Elhamaida, S.M., Elsamad, A., Abd Elfatah, M. (2025). Project navigating: A guide to successful construction project management. Advanced Sciences and Technology Journal, 2(1): 1-27. https://doi.org/10.21608/astj.2025.345552.1030

[12] Arar, A.J., Poirier, E., Staub-French, S. (2025). A research and development framework for integrated project delivery. Construction Management and Economics, 43(2): 85-112. https://doi.org/10.1080/01446193.2024.2390529

[13] Stephen, S.S., Oke, A.E., Aigbavboa, C.O., Akinradewo, O.I., Adetoro, P.E., Ikuabe, M. (2025). Lean practices for stealth construction. In Stealth Construction: Integrating Practices for Resilience and Sustainability, Emerald Publishing Limited, Leeds, pp. 129-161. https://doi.org/10.1108/978-1-83608-182-120251006

[14] Waqar, A., Nisar, S., Qadir, S. (2025). BIM-driven sustainable safety management solutions for downstream oil and gas (DO &G) construction projects. Environmental Challenges, 18: 101058. https://doi.org/10.1016/j.envc.2024.101058

[15] Stephen, S.S., Oke, A.E., Aigbavboa, C.O., Akinradewo, O.I., Adetoro, P.E., Ikuabe, M. (2025). General Introduction to Stealth Construction. In Stealth Construction: Integrating Practices for Resilience and Sustainability, Emerald Publishing Limited, pp. 1-18. https://doi.org/10.1108/978-1-83608-182-120251001

[16] Toochukwu, A.C. (2025). Sustainable construction practices: Balancing cost efficiency, environmental impact, and stakeholder collaboration. International Research Journal of Modernization in Engineering Technology and Science, 7(1): 4118-4140. https://doi.org/10.56726/IRJMETS66703

[17] Singh, T., Amanda, S., Oladele, S., Coadic, K. (2025). Cross-industry comparison of lean six sigma applications: Insights for engineering project management.

[18] Santos Fonseca, S., Aguilera Benito, P., Piña Ramírez, C. (2025). Development and application of an innovative planning and monitoring tool to optimize construction projects. Buildings, 15(2): 160. https://doi.org/10.3390/buildings15020160

[19] Chen, L., Darko, A., Chan, A.P. (2025). Green construction project management methodologies and frameworks. In Developing a Body of Knowledge for Green Construction Project Management, World Scientific Pub Co. Inc., pp. 107-131. https://doi.org/10.1142/9789811251429_0004

[20] Gheda, M.L.M., Chung, H.W., Aziz, F.F.A., Nusran, N.F.M. (2025). Bridging the digital divide: Overcoming challenges in technology adoption in Malaysia’s construction industry. Malaysian Journal of Social Sciences and Humanities (MJSSH), 10(1): e003137-e003137. https://doi.org/10.47405/mjssh.v10i1.3137

[21] Nwaogbe, G., Ekpenyong, E., Urhoghide, O. (2025). Managing workforce productivity in the post-pandemic construction industry. World Journal of Advanced Research and Reviews, 25(1): 572-588.

[22] Stephen, S.S., Oke, A.E., Aigbavboa, C.O., Akinradewo, O.I., Adetoro, P.E., Ikuabe, M. (2025). Value management in stealth construction. In Stealth Construction: Integrating Practices for Resilience and Sustainability, Emerald Publishing Limited, pp. 197-214. https://doi.org/10.1108/978-1-83608-182-120251008

[23] Ruzieh, A.S. (2025). Advancing middle east construction sustainability: A framework for addressing logistics challenges through solutions and critical success factors. Sustainability, 17(2): 533. https://doi.org/10.3390/su17020533

[24] Tembo, C.K., Muleya, F., Kajimo-Shakantu, K. (2025). Advocating for facilities management through the various BIM dimensions. In Development and Investment in Infrastructure in Developing Countries: A 10-Year Reflection, CRC Press, pp. 206-214. https://doi.org/10.1201/9781003483519-23

[25] Dugbartey, A.N., Kehinde, O. (2025). Optimizing project delivery through agile methodologies: Balancing speed, collaboration and stakeholder engagement. World Journal of Advanced Research and Reviews, 25(1): 1237-1257. https://doi.org/10.30574/wjarr.2025.25.1.0193

[26] Wang, S., Lu, Y., Lu, J., Mao, Y., Wang, N., Guo, Z. (2025). Exploring practitioners’ perceptions of digital delivery in modular integrated construction projects. Journal of Management in Engineering, 41(2): 04024070. https://doi.org/10.1061/JMENEA.MEENG-6304

[27] Ramadhan, J.S., Waty, M. (2025). Impact of change orders on cost overruns and delays in large-scale construction projects. Engineering, Technology & Applied Science Research, 15(1): 20291-20299. https://doi.org/10.48084/etasr.9449

[28] Stephen, S.S., Oke, A.E., Aigbavboa, C.O., Akinradewo, O.I., Adetoro, P.E., Ikuabe, M. (2025). Procurement in stealth construction. In Stealth Construction: Integrating Practices for Resilience and Sustainability, Emerald Publishing Limited, Leeds, pp. 73-95. https://doi.org/10.1108/978-1-83608-182-120251004

[29] Sahebzamani, E., Forcada, N. (2025). Enhancing sustainable construction decisions: Integrating BIM and VR for circular economy assessment. Building Research & Information, 2025: 1-21. https://doi.org/10.1080/09613218.2024.2449441

[30] Denis, A. (2025). A survey on artificial intelligence and blockchain applications in cybersecurity for smart cities. SHIFRA, 2025(1), 1-45. https://doi.org/10.70470/SHIFRA/2025/001

[31] Almaiah, M.A., Bin Sulaiman, R., Islam, U., Badr, Y., El-Qirem, F.A. (2025). Federated learning in healthcare: A bibliometric analysis of privacy, security, and adversarial threats (2021–2024). SHIFRA, 2025(1), 46-61. https://doi.org/10.70470/SHIFRA/2025/002

[32] Nayyef, Z.T., Abdulrahman, M.M., Kurdi, N.A. (2024). Optimizing energy efficiency in smart grids using machine learning algorithms: A case study in electrical engineering. SHIFRA, 2024(1), 46-54. https://doi.org/10.70470/SHIFRA/2024/006